Challenges and Solutions When Taking Printed Electronics from Lab to Fab

Scaling printed electronic

Scaling printed electronics from the laboratory to large-scale manufacturing presents a unique set of challenges that can impact the efficiency and cost-effectiveness of production processes. In the lab, the primary focus is on innovation and developing new technologies, but as these technologies move towards commercial production, critical factors such as scalability, material costs, consumption rates, and sustainability come into play.

This transition is particularly evident in the development of printed solar cells, where the goal is to produce flexible, cost-efficient devices using advanced manufacturing techniques like Roll-to-Roll (R2R) processing. Initial lab methods, such as spin coating and vacuum deposition, often face limitations in scalability and material efficiency. Addressing these issues involves exploring scalable processing solutions and equipment, such as lab coaters, sheet coaters, and roll-to-roll coaters, which are essential for optimizing production and ensuring a seamless transition from research to full-scale manufacturing.

Lab to Fab - Printed Solar Cells

An illustrative example is the development of printed solar cells, driven by the goal of creating flexible, cost-effective devices through fast Roll-to-Roll (R2R) manufacturing processes with minimal material usage. Initial research involved glass substrates, indium-tin-oxide (ITO) as the transparent front electrode, spin coating for layer deposition, and vacuum deposition for the back electrode.

For years, research concentrated on enhancing organic solar cell efficiency, often keeping cell sizes small to mitigate sheet resistance issues. However, as efficiencies improved, challenges emerged for upscaling: rigid substrates weren't compatible with R2R processing, spin coating led to material waste, indium was costly, and vacuum deposition was not compliant with high-speed manufacturing. Efforts have since then focused on developing easily scalable processing solutions.

Similar approaches can potentially apply to other technologies using printed functional materials, such as fuel cells, printed batteries, Li-ion electrodes, transistors, LEDs, and sensors.

A prime example is the development of printed solar cells, aimed at creating flexible, cost-effective devices through rapid Roll-to-Roll (R2R) manufacturing with minimal material use. Initial research utilized glass substrates, indium-tin-oxide (ITO) as the transparent front electrode, spin coating for layer deposition, and vacuum deposition for the back electrode.

Initially, research focused on improving organic solar cell efficiency, often by maintaining small cell sizes to reduce sheet resistance. As efficiency increased, new challenges arose in scaling up production. Rigid substrates were incompatible with R2R processes, spin coating resulted in material waste, indium proved expensive, and vacuum deposition did not support high-speed manufacturing. Consequently, recent efforts have concentrated on developing scalable processing solutions.

These principles and techniques can also be applied to other technologies using printed functional materials, such as fuel cells, printed batteries, Li-ion electrodes, transistors, LEDs, and sensors.

The Slurry Coater is a precision tool designed for wet film deposition in laboratory-scale R&D, ideal for coating functional materials like battery slurries, perovskite inks, conductive pastes, and sensor formulations

Lab Coaters

Below is a description of different lab-scale coating setups that can be useful in a Lab-to-Fab process:

Spin Coater

One of the most used technique for producing laboratory thin films is spin coating. With spin coating a substrate, normally a glass substrate, is mounted on a chuck that rotates the sample at high-speed while dispensing the liquid onto the sample, this distributing the liquid into a uniform film.

The thickness and uniformity of the spin coated film is dependent on a balance between viscous forces determined from solution viscosity and centrifugal forces controlled by spin speed.

An inherint issue with spin coating is the limited scalability with regards to processing. In contrast to spin coating, linear coating techniques such as blade coating and slot die coating have a better potential to be transferred to large scale manufacturing.

Having laboratory equipment that mimic large-scale manufacturing processes is crucial for developing and optimizing procedures and materials, particularly for transitioning from the development phase to production.

Perovskite Solar Cell Spincoating Timelapse. https://www.youtube.com/@MrNosterp

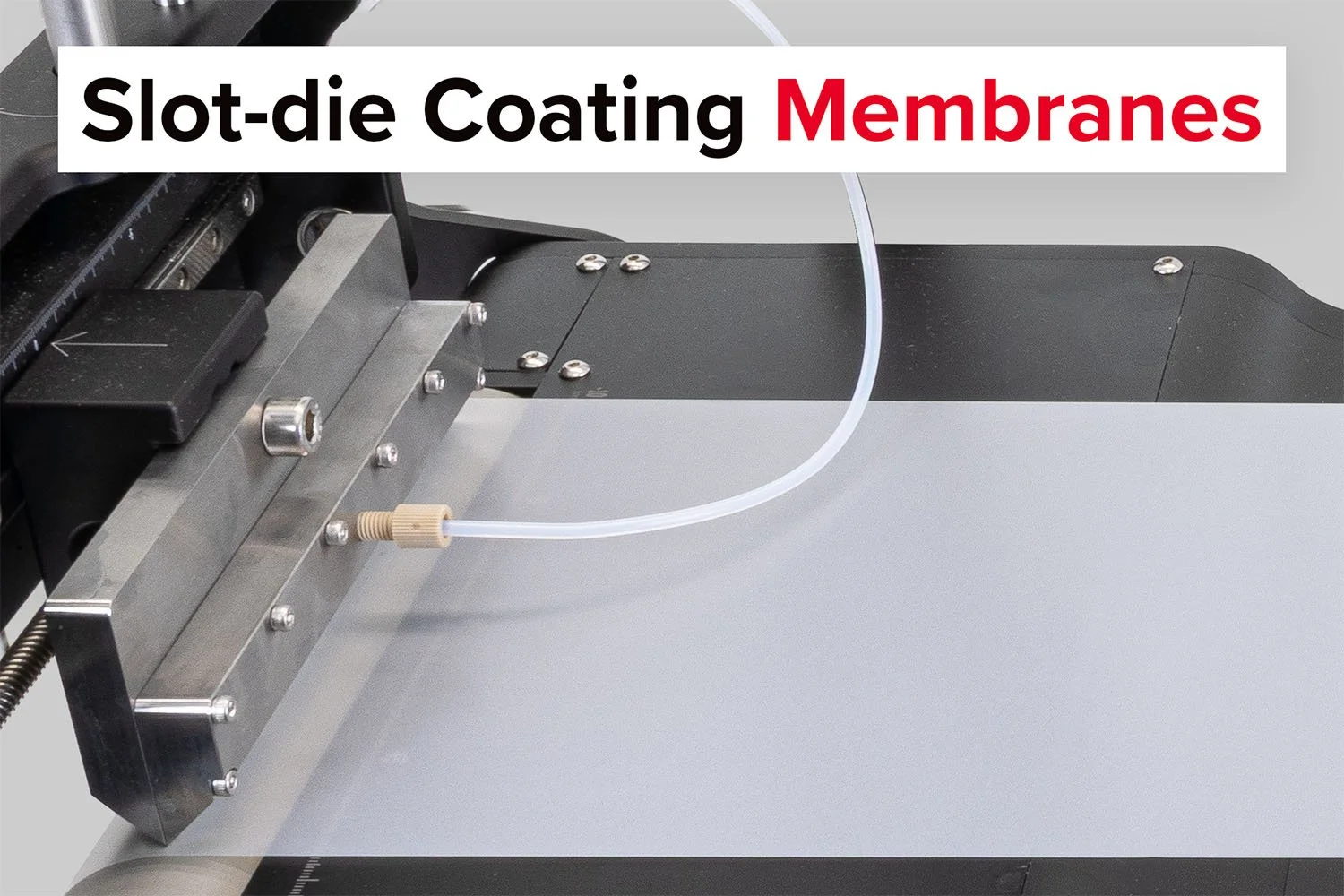

Sheet Coater

The sheet coater is highly versatile for coatings as it accommodates both rigid and flexible substrates. The substrate is secured on a base plate via either tape or a vacuum that utilizes suction to hold it in place. This machine supports various scalable processing techniques such as slot-die coating, knife coating, bar coating, pen coating, and flexo printing with minimal material consumption along the substrate.

Drying is usually carried out by heating the base plate. Unlike the more common hot air drying in R2R processing, this coater's drying method involves heat from below through contact, which can occasionally lead to differences in the dried films, if compared with films of the same materials dried in a R2R process.

Roll-to-Roll Coater

The laboratory R2R coater serves as a compact version of larger coating machines, equipped with various oven types such as hot air/inert gas, IR, and UV. The primary distinction from bigger machines lies in the processing speed, typically limited by the shorter oven length and drying capacity of the lab coater.

One significant advantage of the laboratory R2R coater is its efficiency in terms of material and time required for experiments and process/material optimization. Moreover, the seamless transition of processing conditions to large-scale R2R production is a key benefit, especially in industrial settings or for technologies focusing on large-scale fabrication.

Example of a R2R lab coater.

Lab to Fab - Conclusion

Navigating the shift from laboratory-scale development to large-scale manufacturing in printed electronics is a complex process that requires overcoming significant hurdles related to scalability, material efficiency, and production speed. By employing advanced techniques and equipment—such as lab scale sheet coaters, and lab scale roll-to-roll coaters—researchers and manufacturers can better address these challenges and achieve successful commercialization of technologies. InfinityPV is at the forefront of this evolution, providing innovative solutions that bridge the gap between lab research and industrial production. As the field of printed electronics continues to advance, understanding and adapting to these scaling challenges will be crucial for driving future growth and sustainability in the industry.

Learn More About Lab to Fab

Singer, C., Wach, L., Farnham, E. J., and Daub R. "Insights Into Scalable Technologies and Process Chains for Sulfide-Based Solid-State Battery Production." Batteries & Supercaps, vol. 7, no. 7, 2024, e202400142. https://doi.org/10.1002/batt.202400142.

Creel, E. B., Tjiptowidjojo, K., Lee, J. A., Livingston, K. M., Schunk, P. R., Bell, N. S., Serov, A., Wood III, D. L.. "Slot-Die-Coating Operability Windows for Polymer Electrolyte Membrane Fuel Cell Cathode Catalyst Layers." Journal of Colloid and Interface Science, vol. 610, 2022, pp. 474-485, ISSN 0021-9797, https://doi.org/10.1016/j.jcis.2021.11.047.

Weerasinghe, H. C., Macadam, N., Kim, J. E., et al. "The First Demonstration of Entirely Roll-to-Roll Fabricated Perovskite Solar Cell Modules Under Ambient Room Conditions." Nature Communications, vol. 15, no. 1656, 2024, https://doi.org/10.1038/s41467-024-46016-1.

Marques, M. J. M., Lin, W., Taima, T., Umezu, S. "Unleashing the Potential of Industry Viable Roll-to-Roll Compatible Technologies for Perovskite Solar Cells: Challenges and Prospects." Materials Today, 2024, ISSN 1369-7021, https://doi.org/10.1016/j.mattod.2024.06.013.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.