Master Roll-to-Roll Processing of Printed Solar Cells

Printed Electronics Workshop

Our workshops offer hands-on experience in every step of the printed solar cell manufacturing process, from material and ink preparation to printing, testing, packaging, and final integration. With practical training, you’ll build solid expertise in the field. If you complete our full series of modules, you’ll become a master of roll-to-roll (R2R) printed solar cells.

Tailored Learning with Modular Workshops

Our workshops cover the entire solar cell production process, with modules that allow you to focus on areas that match your existing skills or fill gaps in your knowledge. Each module is designed to be flexible and focused, enabling you to tailor your learning journey.

Hands-On Training

The workshops are primarily practical, with some theoretical sessions on equipment usage and safety. Participants must sign a responsibility declaration upon registration before starting any practical work. We offer 6 action-packed modules, each lasting 9 hours with a one-hour lunch break (lunch included). Workshops can be customized for companies and conducted under an NDA. All materials and expenses are included; travel, breakfast, and accommodation are not.

Students and ECTS Credits

We welcome master’s and PhD students. Depending on your university, the workshops may qualify for ECTS points. At the end of the program, you’ll receive a diploma detailing the course objectives, time commitment, and ECTS equivalent. Please consult your university for external course recognition.

Workshop Highlights

Solar Cell Design – Learn the fundamentals of designing solar cells for specific applications.

Materials Science – Understand the properties of active materials.

Ink Preparation – Formulate and prepare inks for various printing methods.

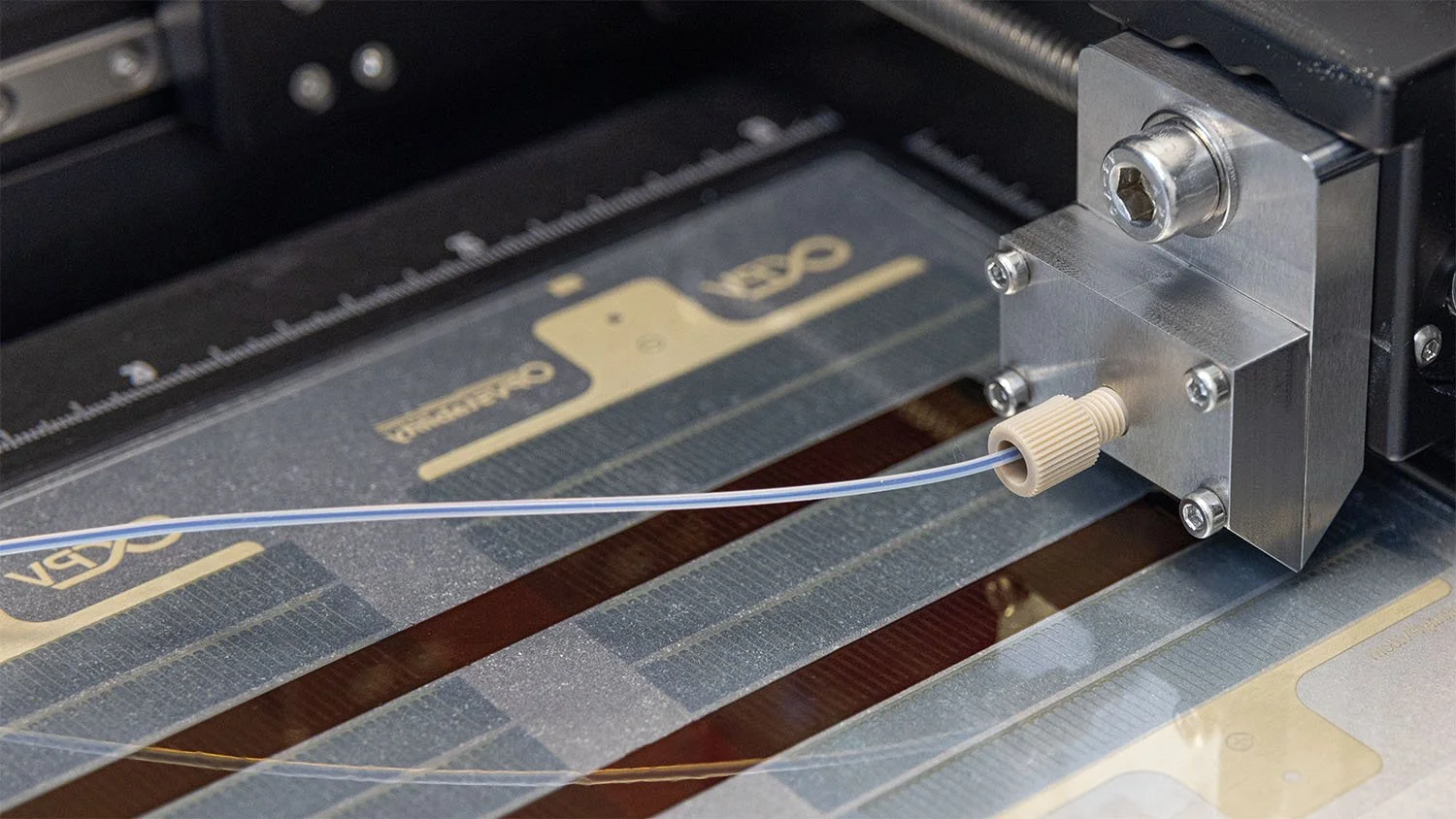

Printing & Coating Techniques – Gain hands-on experience with flexographic printing, slot-die coating (sheet-based and roll-to-roll), and more for solar cell fabrication.

Coating Equipment – Learn to use the Laboratory Roll-to-Roll Coater and Slot-die Coater for precise, scalable printing and coating.

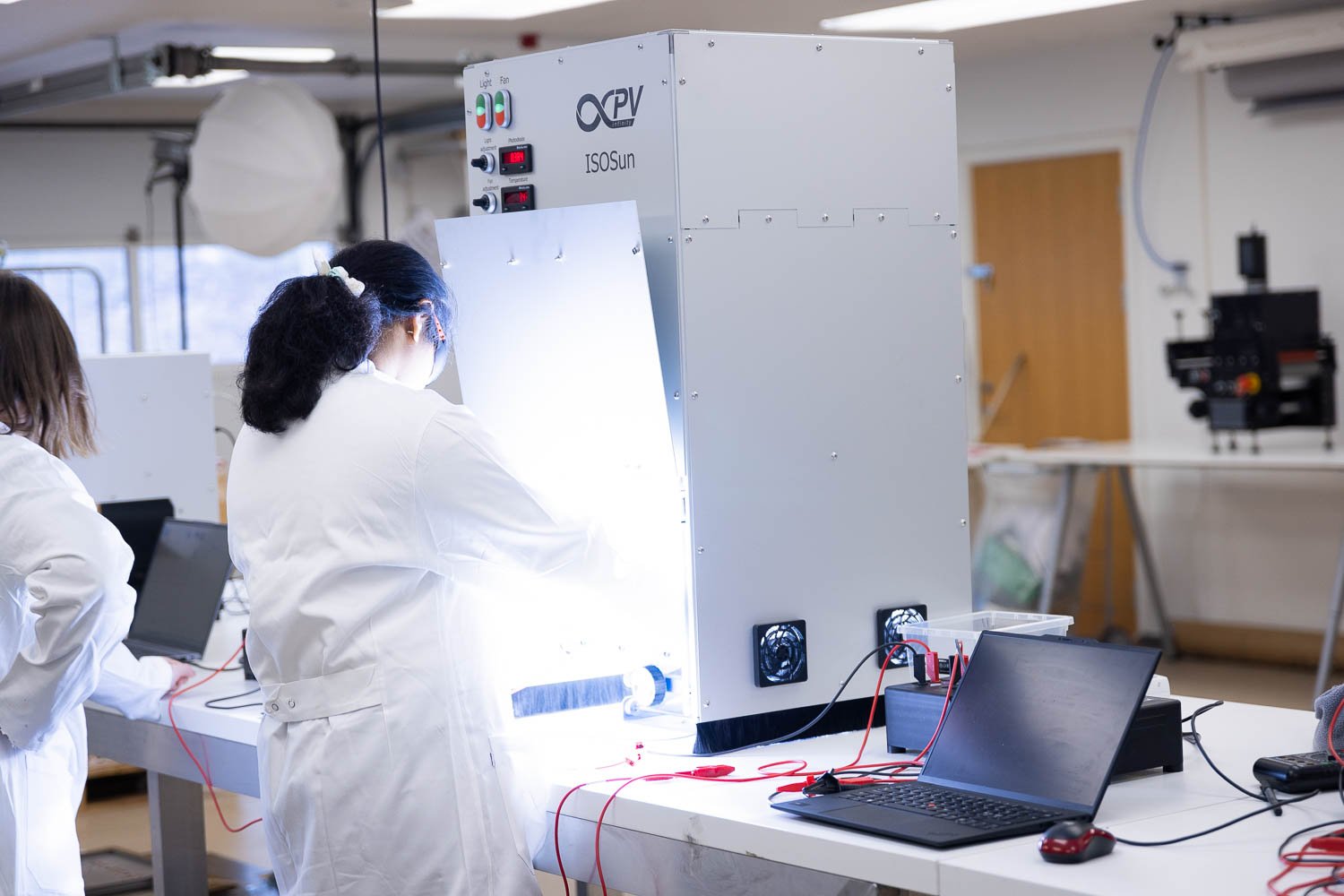

Performance Testing – Evaluate printed solar cells using roll-to-roll methods and performance tools like the ISOSun Solar Simulator, LBIC, and Source Measure Unit.

Lamination & Packaging – Protect and finalize solar cells through roll-to-roll lamination.

Device Handling – Learn to cut and manage devices after printing.

Video: How to Make Solar Cells Using the Slot-die Coater

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater. From preparing the ink and coating the active and hole-conducting layers to printing the silver back electrode. By combining slot-die coating with flexo printing, this method enables efficient and high-quality solar cell production.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.