Roll-to-Roll LBIC

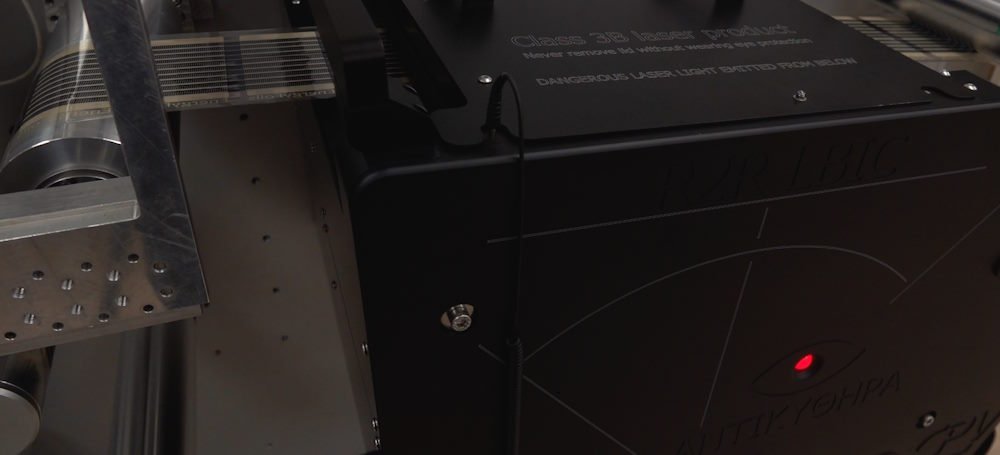

A contactless, non-destructive imaging solution for printed solar cells, enabling high-speed, detailed analysis of photovoltaic performance across endless rolls of solar foil.

Roll to Roll LBIC

We named our roll-to-roll LBIC series after the ancient Greek Antikythera mechanism. While they do not share the same function they share complexity and being way ahead of their time, our time!

When manufacturing printed solar cells it is essential to “see” where the solar cell or modules work (and where they do not). LBIC is just that technique that has been around for a long time as a powerful tool that (almost) grant X-ray vision of your solar foil. LBIC has been used as an indispensable tool for all serious manufacturers of printed solar cells enabling the establishment of causality between processing parameters and final device function.

The missing link has always been how to achieve this for an almost endless solar foil. The Antikythera R2R LBIC does just that allowing for format freedom and contactless LBIC imaging of embedded contacts.

| undefined | Standard value | Limit | Units |

|---|---|---|---|

| Foil width | 350, 700, 1050 | 2100 | mm |

| Foil length | 1000 | infinite | meters |

| Image resolution (pixel size) | 100 | 40 | micron |

| Web speed | 2 | 90 | m/min |

| Laser wavelength | 450 | 1050 | nm |

| Image face | Bottom | Top | NA |

| Integration distance | Foil width | 1/2 Foil width | NA |

| Integration volume | 2.0 x foil width cubed | 1.5 x foil width cubed | Volume |

R2R LBIC for printed solar cell

LBIC imaging has traditionally been viewed similarly to a classic office scanner or a digital camera. This works great for imaging of objects that has an aspect ratio close to or around 1. This has translated directly into how machines have been built and how electrical contacts have been made. Typically the solar cell or module was placed inside a cabinet on a test surface and electrical contacts established by means of alligator clips or soldered wires. The cabinet is then closed and the LBIC image carefully recorded by scanning a laser across the solar cell for as long as it takes. In other words there is ample time and the imaged object is not moving.

The printed solar cell is a different story. It is typically manufactured on near endless rolls of foil so aspect ratios easily exceed 100 or much more making the cabinet approach impossible let alone handling the electrical contact. For decades we worked on this seemingly simple challenge and finally evolved LBIC to the level it has today. There are several inventive steps that need to be made to go from the sheet based solar cell to the roll. The most critical ones are speed, noise, electrical contacts, data handling, image processing and defect detection (the list is much longer). We tirelessly addressed these in turn and finally came up with the current version of LBIC. What better name to coin the invention with than Antikythera that signals wisdom, advanced thinking and being way ahead of imaginable competition.

Anybody that prints solar cells will need the Antikythera LBIC to maximize processing speed and yield, to document quality on the fly. The method is completely non-destructive and simply leaves you a very large image detailing the photovoltaic function of every pixel on your very long roll of solar cells.

Many potential clients already have a working roll-to-roll line and will question whether it can be retrofitted to an existing machine. The answer is yes, easily! The Antikythera machine is a self contained unit that does not need anything other then a low power 110-240 VAC line voltage source. The machine takes care of web speed acquisition etc. all by itself and can easily be interfaced to existing hardware and software. The installation can be above or below the moving web and the volume (footprint) is quite flexible. A general rule is that the installation volume is around 1.5 x the foil width cubed so not a lot of space is needed.

Roll-to-roll LBIC has been developed over many years and has been supported by many public funded projects. The early start was already in 2012 with the Clean4yield project headed by TNO (EU H2020 project No.: 281027) and since then many projects have contributed to the developments and most recently the very successful RealNano project headed by Aristotelio Panepistimio Thessalonikis (EU H2020 project No.: 862442).

We Are Ready to Help You

With decades of experience in printed solar cells, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Master Roll-to-Roll Processing of Printed Solar Cells

Join our hands-on printed electronics workshop and gain practical experience in every step of printed solar cell manufacturing, from ink preparation to testing and final integration. You’ll master solar cell design, printing, coating, and performance testing, using the latest equipment like the Laboratory Roll-to-Roll Coater, Slot-die Coater, LBIC, ISOSun Solar Simulator and Source Measure Units. Tailored to your needs, our workshops are perfect for students seeking ECTS credits or professionals wanting to expand their expertise.