Materials Testing

We offer comprehensive testing of your solar cell materials on flexible substrates using industrial-scale processing equipment.

Expertise in Roll-to-Roll Processing and Upscaling Platform

With extensive experience in roll-to-roll processing of flexible organic solar cells, we specialize in optimizing the fabrication of each component in the solar cell stack to maximize performance. Our skilled team, combined with advanced equipment, ensures that your materials undergo testing that facilitates the transition from research to product development, upscaling, and manufacturing. We offer testing on our upscaling platform with flexible substrates, giving you insights into large-scale fabrication while minimizing material consumption.

Minimal Material Requirements & Flexible Testing Options

For upscaling tests, we require only 20-250 mg of active material, depending on the type of studies. You don’t need to disclose your material composition, and we can test multiple material candidates or batches. Testing combinations can be tailored to your specific needs.

Comprehensive Test Preparation, Packaging, and Stability Testing

We provide preparation of both single cells and modules, with encapsulation/packaging options using glass or flexible barrier substrates. In addition, we conduct short accelerated stability tests using concentrated light (100-200 suns) or ISOS-L-2, comparing your material to standard references such as P3HT:PCBM.

Detailed Data Reporting and Support

The resulting data, including solar cell processing parameters, IV-curves, and stability, will be compiled into a comprehensive report that supports your ongoing material research, development, and publication efforts.

Material Testing & Roll Processing Expertise: Test solar cell materials on flexible substrates using industrial-scale roll-to-roll processing equipment. Optimize each component in the solar cell stack for improved performance, transitioning research into product development, upscaling, and manufacturing.

Upscaling Platform & Minimal Material Requirements: Testing available on upscaling platform with flexible substrates. Small material consumption: 20-250 mg of active material needed for upscaling tests (depending on the study). No need to disclose material composition for testing.

Multiple Materials & Flexible Testing Options: Multiple material candidates or batches can be tested simultaneously with flexible testing options based on specific needs.

Cell & Module Preparation, Encapsulation/Packaging: Preparation of single cells or modules, with encapsulation/packaging options using glass or flexible barrier substrates.

Accelerated Stability Testing & Standard Reference Comparison: Short stability tests with concentrated light (100-200 suns) or ISOS-L-2, comparing your material to standard reference materials like P3HT:PCBM.

Data Reporting & Research Support: Compiled report including processing parameters, IV-curves, and stability data, which can be used for further material research, development, and publication.

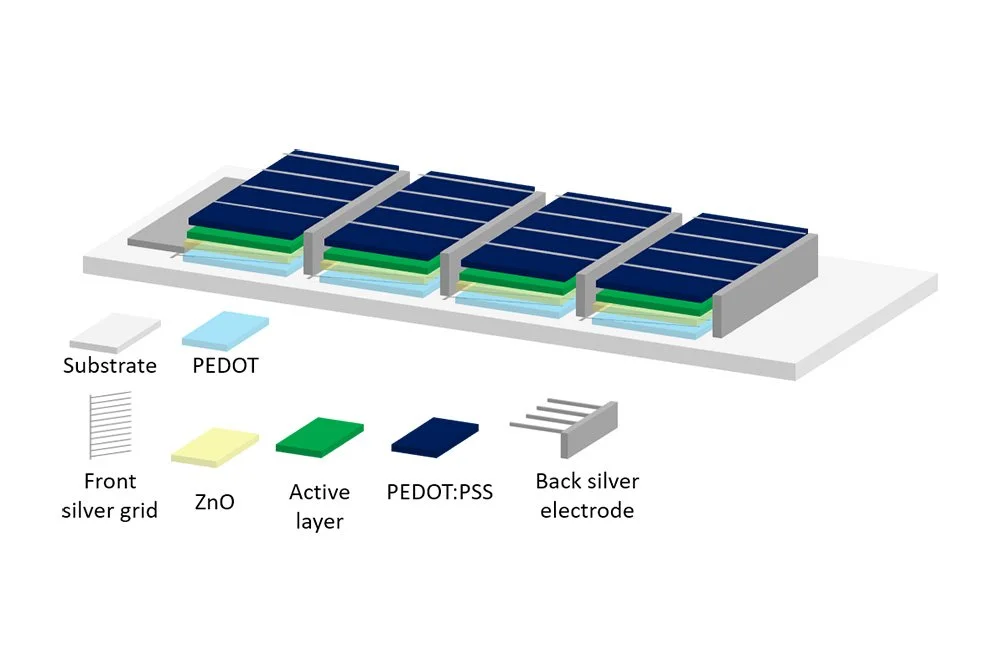

Schematic Representation of a Module Consisting of Four Sub-devices With an Inverted Geometry on Flexible Substrate.

Examples of Standard Tests of Active Layer Materials

Slot-die coating of active layer by tuning the thicknesses, web speed, flow of solution, donor:acceptor ratio, solvent and/or coating temperature.

Single cells with active area of 1-7 cm2

Modules with 2-8 cells with an active area of 2-50 cm2

Encapsulation with glass and/or flexible barrier foils

Stability tests according to ISOS recommendations more info

(The active material being either acceptor, donor or blend materials. All devices and modules are prepared with inverted geometry on our high performing flexible substrate using slot-die coating under atmospheric conditions.)

Build Your Own R2R Lab Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.