Silver Nanowires Explained: How They Work and Their Role in Nanoelectronics

What are Silver Nanowires?

Silver nanowires (AgNWs) are ultra-thin, elongated structures composed of silver, typically measuring from 10-200 nanometer in diameter and with a length of 10-40 micron. Known for their exceptional electrical conductivity and flexibility, these nanowires can form transparent conductive films, making them ideal for use in a variety of applications, including touchscreens, solar cells, and flexible electronics. For high transparency, the general rule is the thinner and longer the silver nanowires the better. Due to their high aspect ratio (length-to-diameter ratio), silver nanowires can create extensive interconnectivity within a film, enhancing performance in electronic devices. Additionally, silver nanowires exhibit unique optical properties, such as surface plasmon resonance, which can be harnessed in sensing and imaging technologies. With scalable production methods and versatile functionality, silver nanowires represent a significant advancement in the field of nanotechnology, paving the way for innovative applications across multiple industries.

History of Silver Nanowires

The journey of silver nanowires began with the pioneering studies in the field of nanomaterials, which saw a growing interest in nanoscale structures and their physical, chemical, and electrical properties. In the early 2000s, researchers demonstrated that silver nanowires could be synthesized through various methods, including chemical reduction, template-assisted synthesis, and electrochemical deposition. Among these methods, the chemical reduction method emerged as a popular approach due to its relative simplicity and versatility, allowing for the controlled synthesis of silver nanowires with specific dimensions and morphology.

Over time, significant advancements have been made in optimizing the synthesis processes to enhance the properties of silver nanowires. One thing that has been explored extensively is the use of different surfactants, stabilizers, and solvents to improve dispersion stability and prevent nanowire aggregation, which is crucial for maintaining a homogenous ink – an essential for preparing a homogenous film with high conductivity in the final application. Also, huge efforts have been put into the development of silver nanowires with tailored aspect ratios, which are pivotal in defining their conductive properties.

The emergence of flexible electronics and the demand for transparent conductive materials has been a serious motivator for the exploration of silver nanowires, because of the potential for substituting traditional materials like indium tin oxide (ITO), which is both brittle and contains the scarce material indium. Additionally, efforts towards the development of hybrid materials, combining silver nanowires with other nanostructures, have opened new avenues for enhancing functionality beyond simple conductivity, such as photonic applications and advanced sensor technologies.

The fact that the silver nanowires are solution processable furthermore enables the use of large-scale manufacturing methods such as slot-die coating, spray coating, and inkjet printing. This has facilitated the application of silver nanowires in real-world devices, including touch screens, organic light-emitting diodes (OLEDs), thin-film solar cells, and flexible sensors. With the growing use of silver nanowires the need for elucidating the performance characteristics and degradation mechanisms of silver nanowires films has become increasingly important. More and more effort has therefore been put into gaining deeper understanding of their reliability in various environmental conditions.

In flexible technologies like foldable phones, silver nanowires are used to create transparent, conductive films that enable touch sensitivity and display functionality, while maintaining flexibility and durability, even when the device is folded or bent.

Applications of Silver Nanowires

Silver nanowires have gained significant attention due to their remarkable properties, leading to a wide array of applications in various industries, especially in the fields of electronics, energy, and materials science. Some of the key applications include:

1. Flexible Electronics

Silver nanowires are ideal for use in flexible electronics because they can be integrated into thin, bendable substrates without sacrificing performance. Their high electrical conductivity and mechanical flexibility allow them to be used in wearable devices, flexible displays, and sensors. Silver nanowires are often used in transparent conductive films, making them a replacement for brittle materials like indium tin oxide (ITO), which is commonly used in touchscreens, solar cells, and OLEDs.

2. Transparent Conductive Films

Silver nanowires are extensively used to create transparent conductive films, which are essential in many modern electronics. They are an attractive alternative to ITO, offering superior conductivity, flexibility, and cost-effectiveness. These films are crucial in applications like touchscreens, displays, and solar cells. Because of their high aspect ratio and the ability to form extensive interconnections within a film, silver nanowires create highly conductive networks that allow for efficient electron flow while maintaining optical transparency.

3. Solar Cells

The unique properties of silver nanowires make them ideal for use in thin-film solar cells. They are used as the conductive layer in these solar cells, helping to collect and transport electricity generated from sunlight. Silver nanowires improve the performance of these solar cells by providing better conductivity and a more flexible structure compared to traditional materials. Additionally, silver nanowires are an excellent candidate for perovskite solar cells, a rapidly growing area in solar energy technology.

4. Organic Light-Emitting Diodes (OLEDs)

Silver nanowiress are increasingly used in OLEDs, where they serve as transparent conductive electrodes. Their high conductivity and transparency are ideal for the efficient operation of OLEDs, which are used in everything from smartphones to TVs. The use of silver nanowires helps in improving the efficiency and flexibility of OLEDs, enabling new applications in bendable displays and light-emitting fabrics.

Silver nanowires are a class of one-dimensional nanomaterials composed of silver, typically with diameters ranging from 10 to 200 nm and lengths from 5 to 200 μm. Image credit: Novarials.

5. Sensors

Silver nanowires are also employed in various sensor applications, particularly in gas sensing and biosensing. The surface plasmon resonance properties of silver nanowires enhance the sensitivity of sensors, allowing them to detect small changes in the environment or biological systems. They can be used to create highly sensitive sensors that are lightweight, flexible, and capable of working in a variety of environments.

6. Heaters and Anti-fogging Devices

Due to their excellent electrical conductivity, silver nanowires are being used in the development of transparent film heaters and anti-fogging devices. These applications benefit from the ability of silver nanowires to efficiently conduct heat, making them suitable for use in automotive windows, glasses, and electronic screens where fogging is a concern.

7. Energy Storage and Batteries

Silver nanowires are also being explored for use in energy storage devices such as supercapacitors and batteries. They are used as conductive additives in electrodes to enhance the overall performance of energy storage devices. Their high conductivity and flexibility contribute to improved charge/discharge rates, which are essential for the development of high-performance batteries and supercapacitors.

The versatility of silver nanowires, along with their remarkable electrical, optical, and mechanical properties, makes them an indispensable material for a wide range of emerging technologies, from consumer electronics to renewable energy. As research and manufacturing techniques continue to evolve, the potential applications for silver nanowires are expected to expand even further, revolutionizing various industries.

The Slurry Coater is a precision tool designed for wet film deposition in laboratory-scale R&D, ideal for coating functional materials like battery slurries, perovskite inks, conductive pastes, and sensor formulations

Production of Silver Nanowires

As mentioned, a large variety of synthetic methods have been developed for the preparation of silver nanowires, typically by reduction of silver ions in a glycerol or polyol environment. Often the growth of the silver nanowires is initiated by use of various seed crystals. The major bottle necks in silver nanowires production are 1) the batch variation and 2) the purification/up-concentration of the silver nanowires. Synthesis has traditionally been carried out in beakers/flasks and timing and complete control of temperature profiles has here proven to be crucial in order to obtain the same result – something that complicates upscaling. Another general complication in upscaling is the purification, where large volumes of reaction mixture need to be centrifuged and/or micro-filtrated during workup.

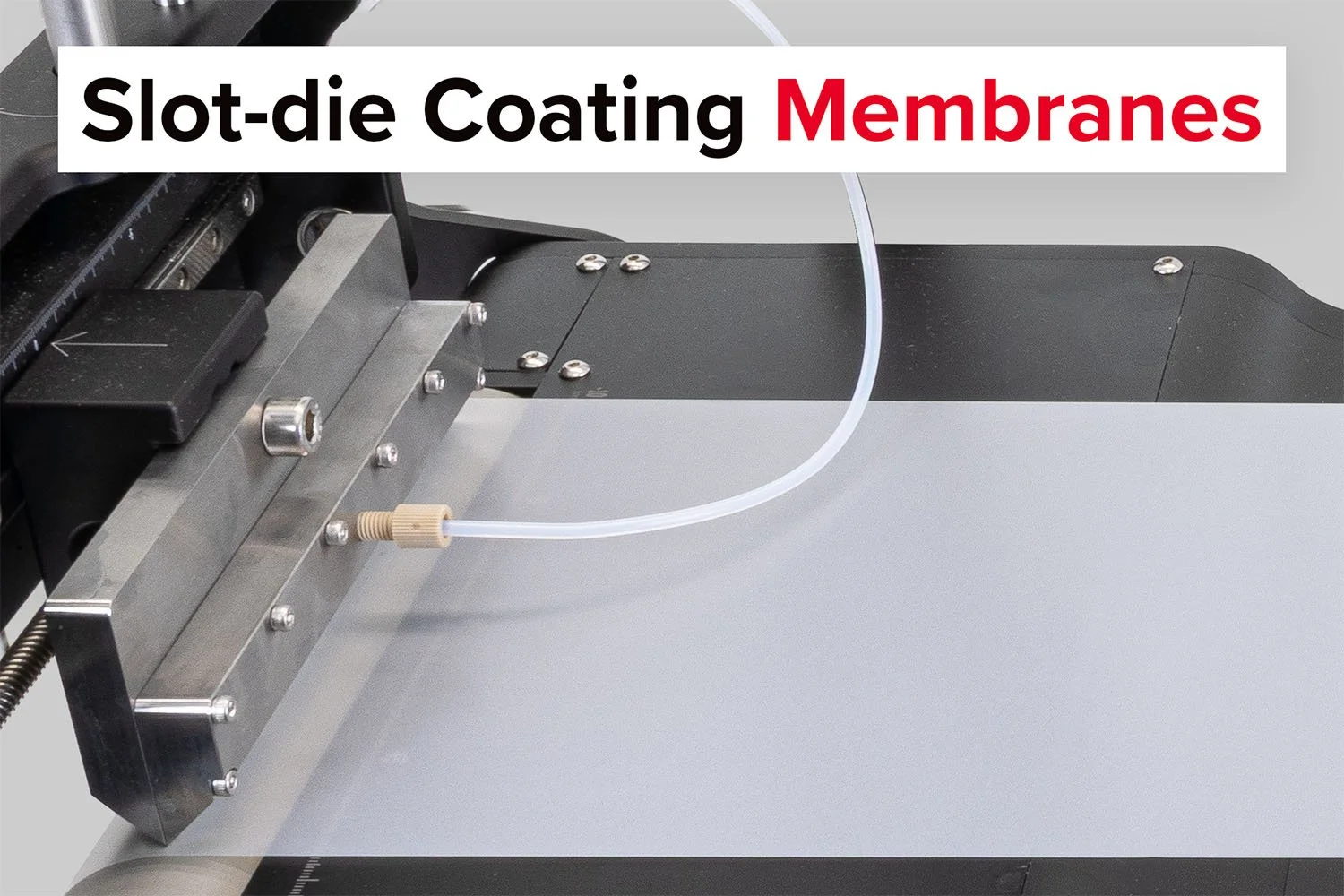

Slot-die Coating of Silver Nanowires

Slot-die coating has become a pivotal technique for processing silver nanowires inks into thin films in printed electronics. This method allows for precise deposition of silver nanowires suspensions by utilizing a specially designed slot-die head, where the dimensions (width, height, and shape) of the coated film are controlled by adjusting pumping rate and coating speed. Especially for coating of large areas the design of the slot-die head critically influences the flow dynamics of the nanowire solution, and a well-engineered slot-die head facilitates the achievement of uniform coating thickness over large substrates, which is essential for high-quality films.

To ensure an optimal coating process, the viscosity, surface tension, and concentration of the silver nanowires suspension must be carefully balanced. The behaviour of these suspensions, whether Newtonian or non-Newtonian, plays a significant role in the resulting coating quality.

Discover everything you need to know about slot-die coating in our comprehensive guides.

Advantages of Slot-Die Coating for Silver Nanowires

Slot-die coating offers several advantages that make it particularly suited for the deposition of silver nanowires in printed electronics:

Scalability: The technique is amenable to large-scale production, supporting the continuous manufacturing of devices.

Uniformity and Thickness Control: Precise control over film thickness and uniformity allows for the tailoring of electrical and optical properties.

Minimal Waste: The method utilizes precise dosing, reducing material waste compared to other deposition techniques, which is particularly beneficial given the cost of silver.

Flexible Substrates: Slot-die coating is compatible with various flexible substrates such as PET, which are needed for the development of bendable electronic devices.

Challenges in Slot-Die Coating of Silver Nanowires

Despite its advantages, the slot-die coating process faces several challenges:

Patterning: Although some patterning is possible with slot-die coating, the techniques is limited to coating of stripes with a certain length, width and hight. True patterning is can only be achieved by printing techniques.

Dispersion Stability: Maintaining a stable dispersion of silver nanowires is crucial. The use of additives or surfactants can help, but they may also disrupt the electrical properties. Research into eco-friendly stabilizers that do not significantly impair conductivity is ongoing.

Film Integrity and Uniformity: Achieving a homogeneous film without defects like cracks or voids is challenging, especially at higher coating speeds. Optimizing the drying process is critical to preventing such defects.

Adhesion to Substrates: Silver nanowires films must adhere well to the substrate to endure mechanical stress. Efforts are therefore put into exploring various surface treatments and adhesion promoters to enhance film-substrate interactions.

Conclusion and Future Outlook

Silver nanowires (AgNWs) have proven to be transformative in advancing nanoelectronics and transparent conductive materials. Their exceptional electrical conductivity, optical transparency, and flexibility make them a strong contender for replacing traditional materials like indium tin oxide (ITO), especially in applications like touchscreens, flexible electronics, and solar cells. Slot-die coating has emerged as a crucial method for large-scale processing of silver nanowire films, offering precise control, scalability, and minimal material waste. While challenges such as dispersion stability, adhesion, and uniformity remain, ongoing research and development continue to address these hurdles, paving the way for more reliable and efficient applications.

In the future, the integration of silver nanowires with hybrid nanomaterials could open up new functionalities beyond conductivity, such as enhanced photonic applications and advanced sensing technologies. Moreover, the exploration of eco-friendly stabilizers and scalable, cost-effective production methods will likely play a pivotal role in broadening the adoption of silver nanowires in commercial and industrial applications. As the demand for sustainable and flexible electronic solutions grows, silver nanowires will undoubtedly remain a cornerstone material, driving innovation across multiple industries and enabling the development of next-generation electronic devices.

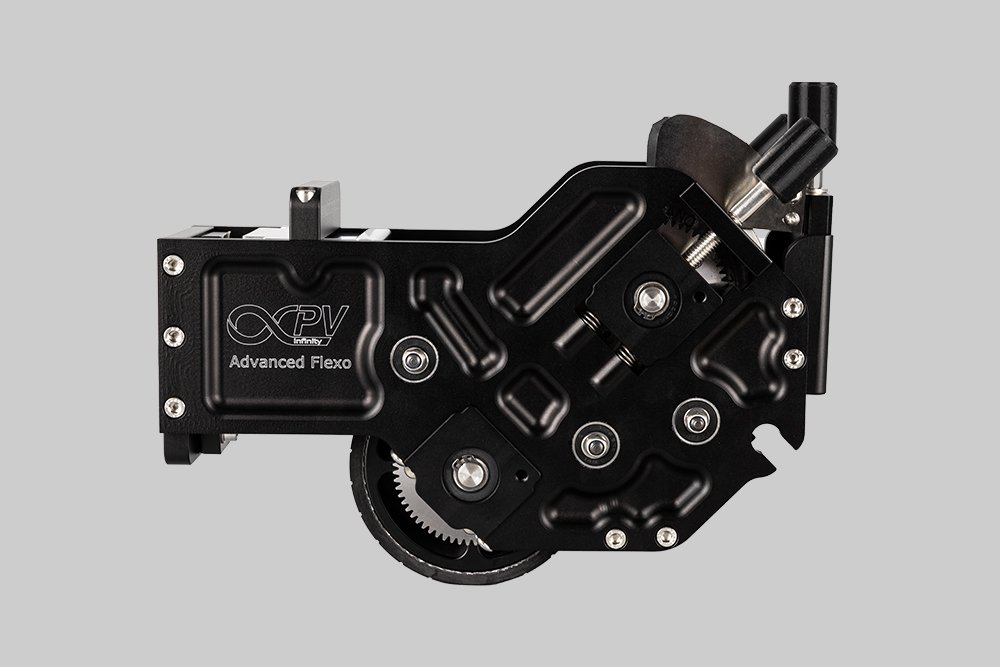

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.