Laboratory Roll-to-Roll Coater Customizer

You have selected a wide system.

Was this a mistake? Go here back here.

1. Platforms

The wide platform is available in three lengths with a processing width of up to 280 mm.

Learn more about each platform here.

Finding the ideal balance between size and functionality, the LR2RC750 seamlessly accommodates additional features while remaining a perfect fit for fume hoods or gloveboxes.

For robust drying of thin films, look no further than the LR2RC1000. With three sections designed to host various oven systems, it streamlines coating and printing tasks efficiently.

When ample laboratory space is available and integration of custom instruments is a priority, the LR2RC1500 delivers the necessary length for an expansive R2R line.

2. Mounting Systems

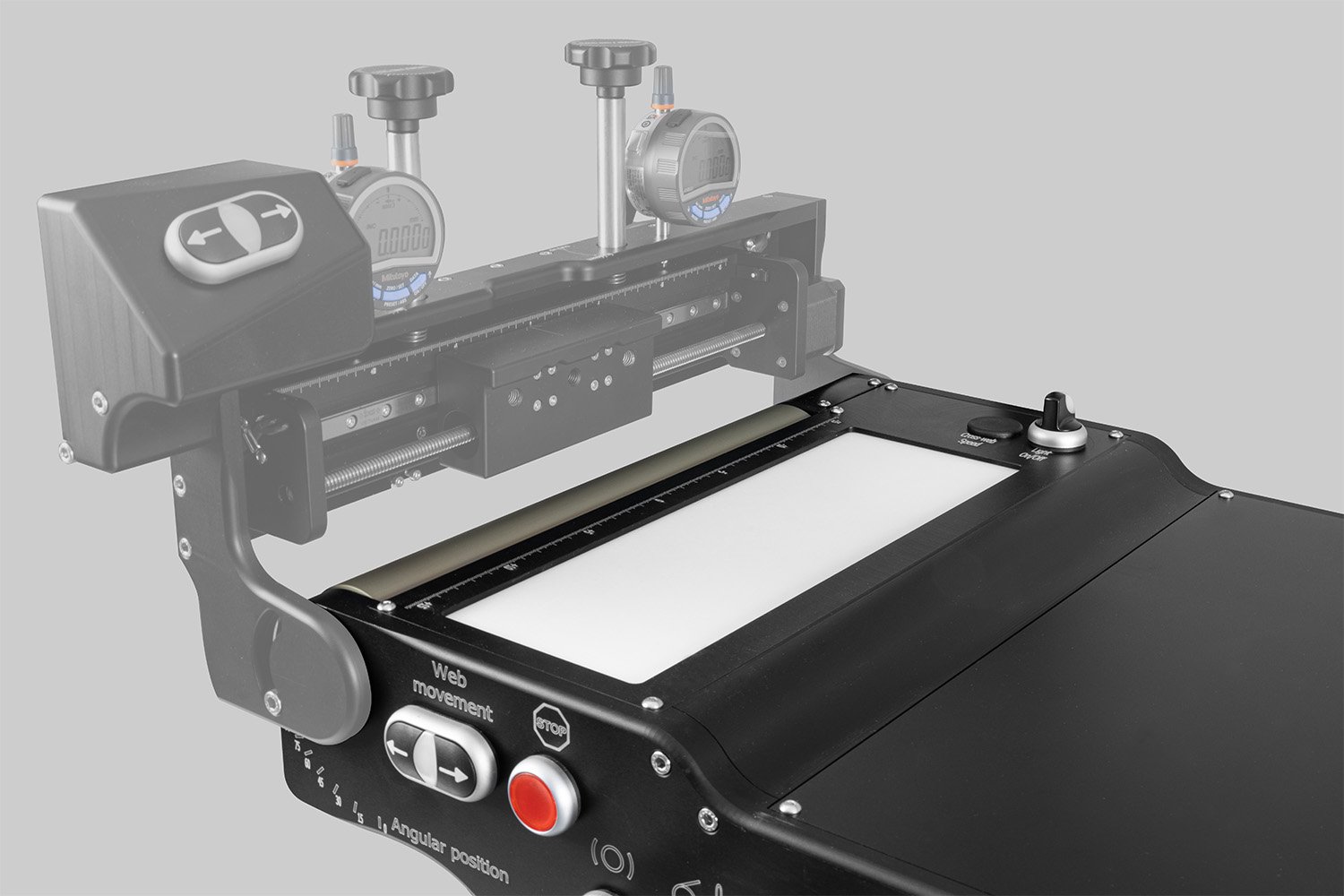

The high-precision angular mounting system is ideal for mounting a slot-die head, a slurry coating setup, or a flexographic printer. The angle can be adjusted from 0 to 90 degrees (9 o'clock to 12 o'clock) which is highly beneficial during both setup and coating.

The advanced mounting system features manual adjustment with digital micrometers to ensure precise head-to-substrate distance control.

PC control of the Laboratory Roll-to-Roll Coater is perfect when working the system from remote - like in a glove box or at synchrotron beamlines.

3. Pumps

The infinityPV syringe pumps, available in Standard (0-20 mL) and Jumbo (0-60 mL) variants, and the Gear Pump both feature a 5-inch color touch screen for intuitive ink flow control. The syringe pumps offer precise delivery for various applications, while the Gear pump provides a continuous flow, handling a wide range of flow rates and fluid types, including non-Newtonian fluids, making them ideal for diverse research and production needs.. Learn more about the syringe pumps here.

Experience precision with syringe pumps, available in Standard (0-20 mL) and Jumbo (0-60 mL) variants.

The infinityPV Mammoth Syringe Pump comes with a 300 ml stainless steel (316) syringe that is resistant to corrosive materials and easy to clean.

The Gear Pump operates based on the rotation of gears, enabling a continuous and consistent flow of liquid.

4. Coating and Printing

The Laboratory Roll-to-Roll Coater supports slot-die heads (available in PEEK, Stainless Steel and Titanium), slurry coaters and flexographic printers. The slot-die heads offer precise coatings for both small details and large surfaces. Heated versions are also available in stainless steel and titanium.

If you need a customized slot-die head tailored to your specific requirements, our expert team is ready to collaborate with you to design and manufacture a solution that meets your exact needs. View video.

The Slurry Coater is a fundamental wet film forming tool, enabling lab scale production of advanced functional thin films. This includes thin film batteries, fuel cells and printed solar cells. View video.

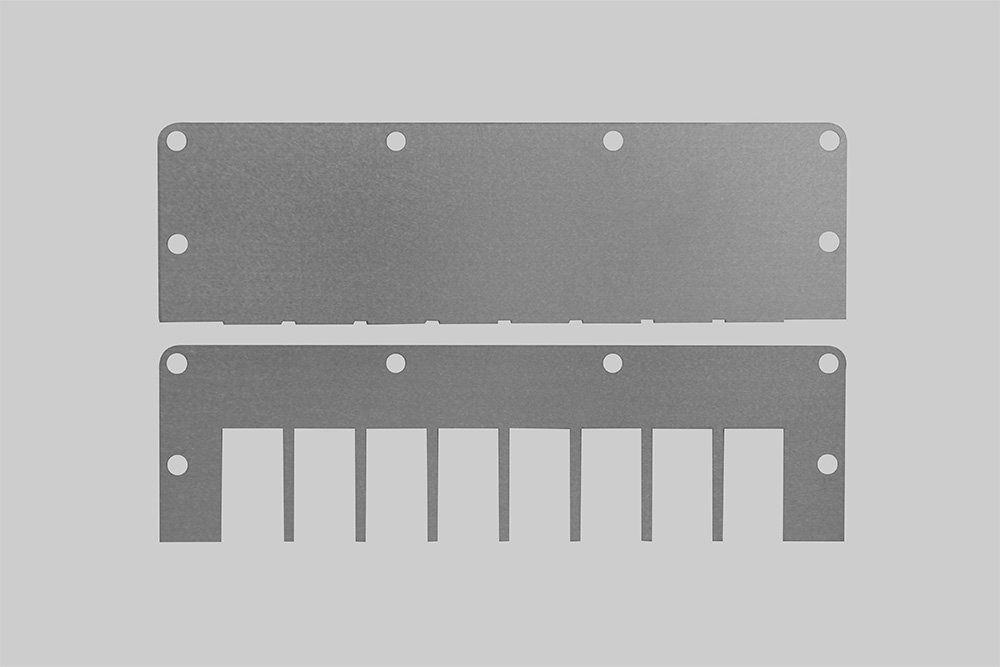

Optimize your slot-die coating systems with our custom shim kits, designed to meet your specific needs and applications. View video.

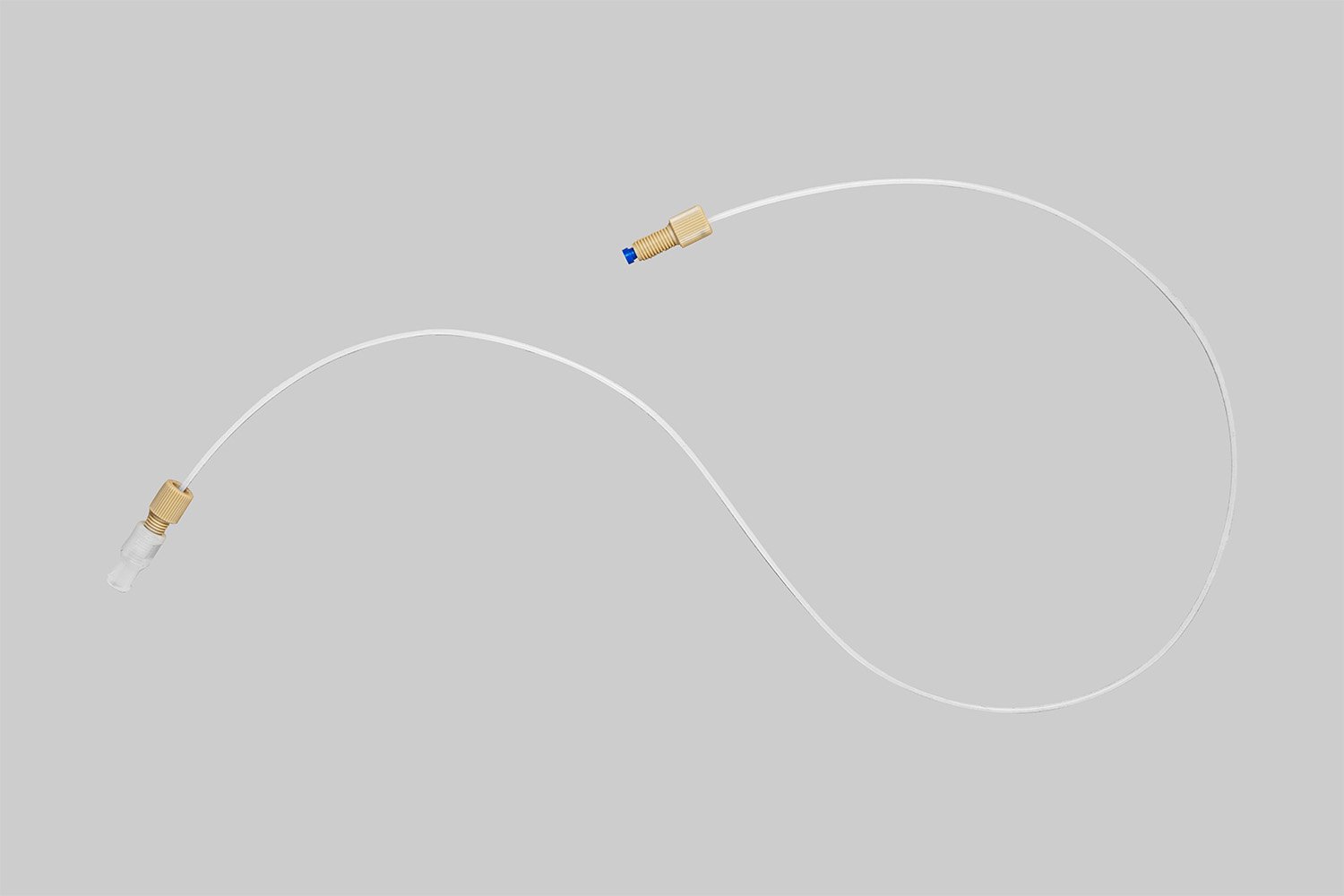

Includes 60 cm of Teflon tubing with a 0.50 mm diameter for low-viscosity inks, and PEEK female Luer lock connectors for secure and reliable connections. View video.

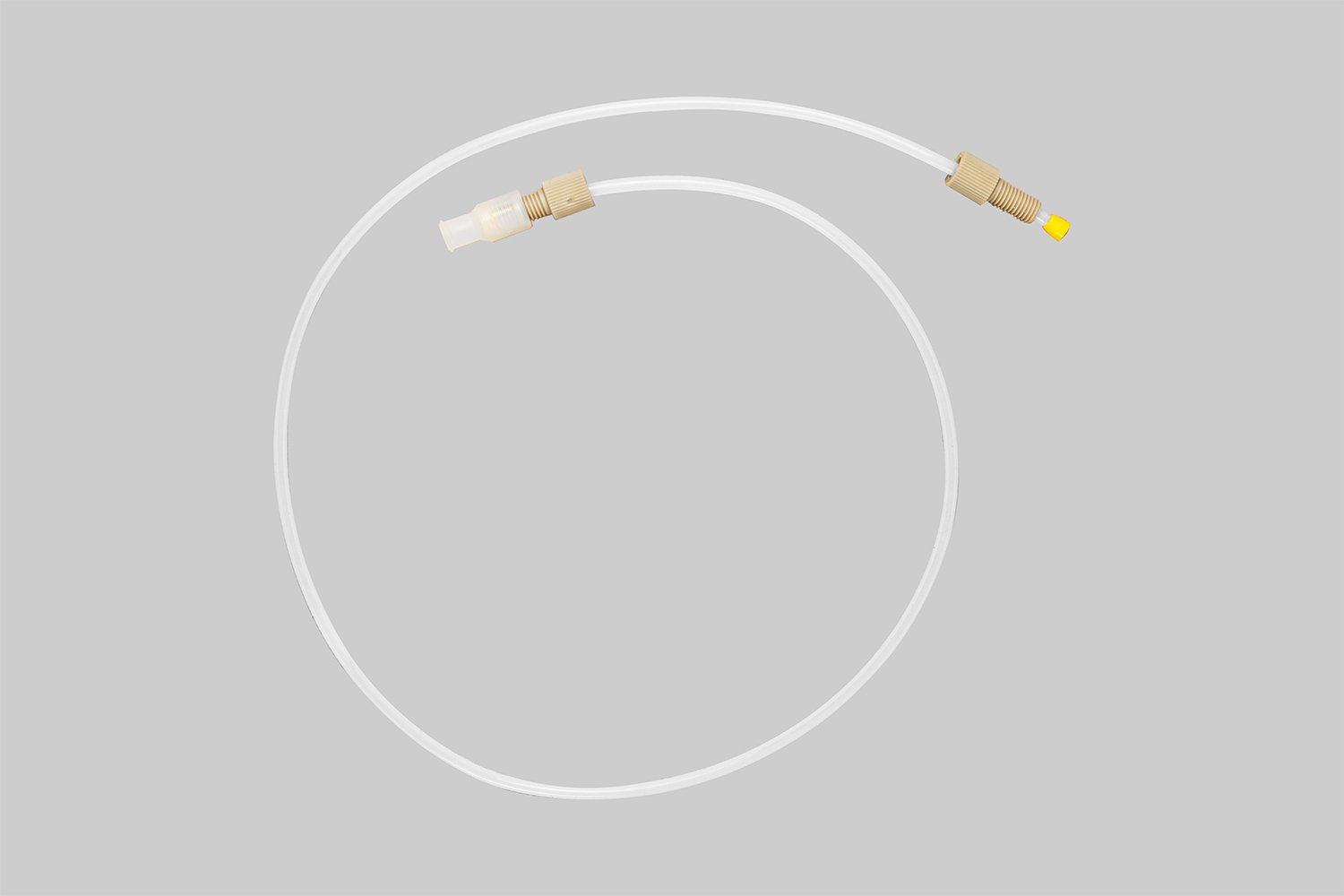

Includes 60 cm of Teflon tubing with a 1.6 mm diameter for high-viscosity inks, along with PEEK female Luer lock connectors to ensure secure connections. View video.

The Roll-to-Roll Flexographic Printer is specially designed for scaled R2R printing. The flexographic printing systems offer customizable printing patterns and widths, ideal for various ink and substrate types.

5. Drying and Curing

The oven systems are designed for the efficient drying and curing of processed thin films. They are known for their compactness and user-friendly features, allowing for seamless addition, removal, or replacement in under a minute. Learn more about the oven systems here.

Enhance your thin-film drying process with the compact inert gas oven. Featuring precise PID temperature control and flexible gas flow options, it's ideal for fast, consistent drying in research and pilot runs. Perfect for solvent evaporation and more.

The UV-LED curing system utilizes LED light sources for fast and efficient curing (photopolymerization) in a wide range of applications, including adhesives and coatings.

This powerful infrared (IR) heat source efficiently transfers heat directly to the material, rather than the surrounding air. Up to 1 kW IR oven with options for curing under inert atmosphere.

Double your drying efficiency with the Double Inert Gas Oven, featuring dual-zone temperature control for critical processes. Ideal for precise, high-performance drying in research and pilot-scale operations.

6. Web Handling

The Laboratory Roll-to-Roll Coater offers exceptional versatility and customization, serving as a multifunctional web handling platform. Choose from a range of web handling components to configure a roll-to-roll system tailored to meet all your specific needs.

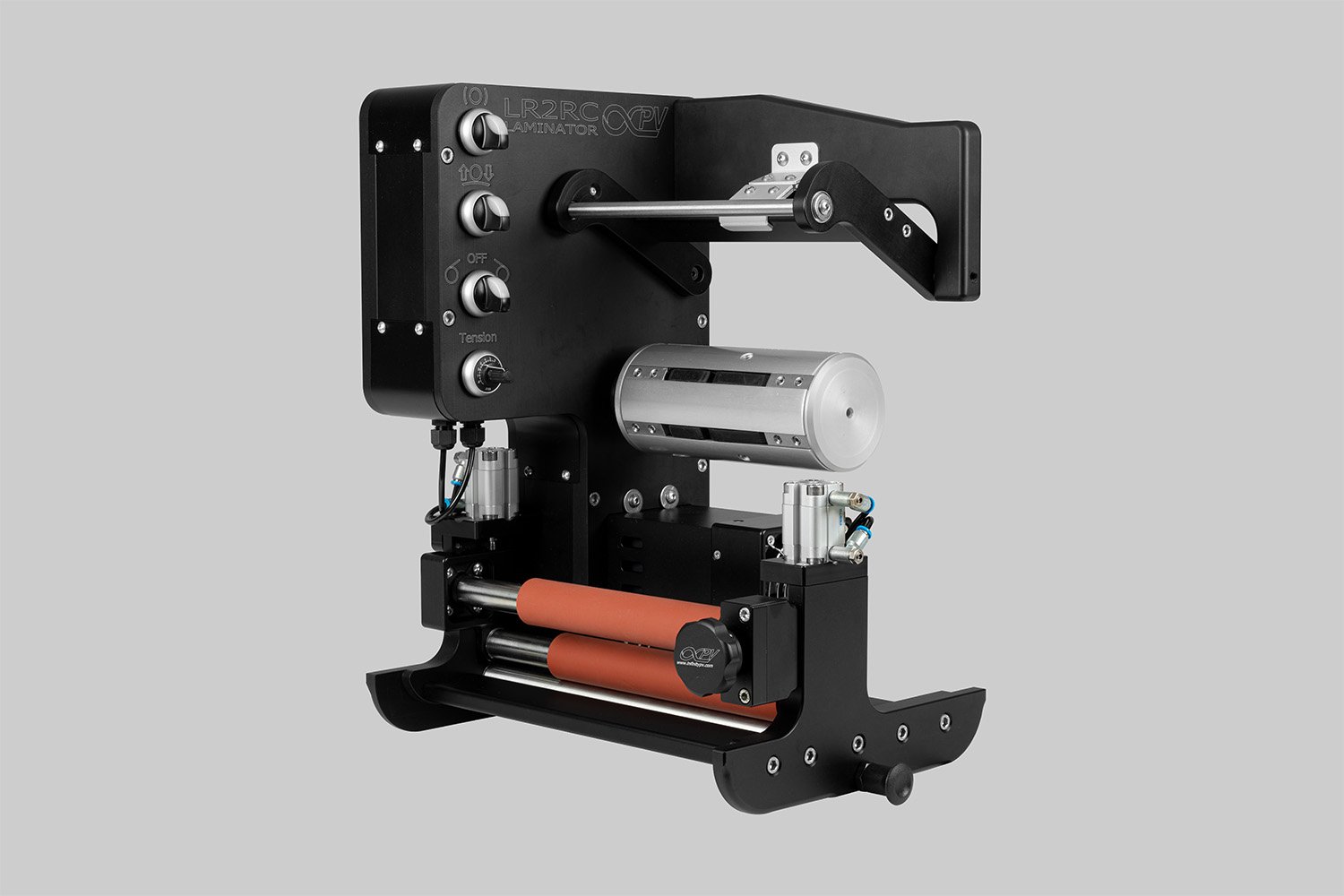

With the Roll-to-Roll Laminator, encapsulation or addition of a protecting liner becomes possible and readily scalable in R2R processing. Watch video.

Cut, trim, slit, and split with ease using the Knife Cutter. It simplifies foil handling with ultra-durable carbide cutters and easily adjustable cutting positions.

The Stripper Unit efficiently removes protective liners or foils just before the coating or printing station, ensuring a clean substrate for precise processing.

Edge guide for high precision alignment of the substrate during operation. Includes basic table on wheels. Delivered as a turnkey system. Including work bench on wheels and 4 additional rollers.

To ensure the highest quality when coating and printing on transparent substrates, adding a light table for immediate post-process inspection is highly advantageous

A powerful and adaptable machine, perfect for enhancing the Laboratory Roll-to-Roll Coater when surface treatment capabilities are needed.

Enables effective surface treatment of polymer-based materials, enhancing their wettability through electrical discharge.

With micrometer screws and a digital display, the Air Knife Pro allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

7. Nip Roller and Simple Laminator

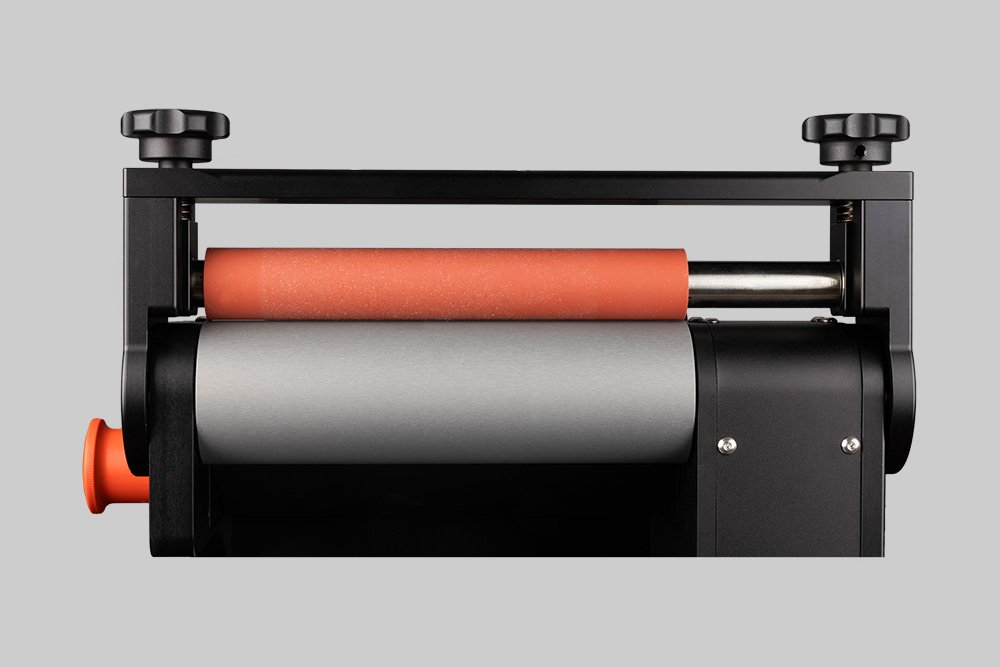

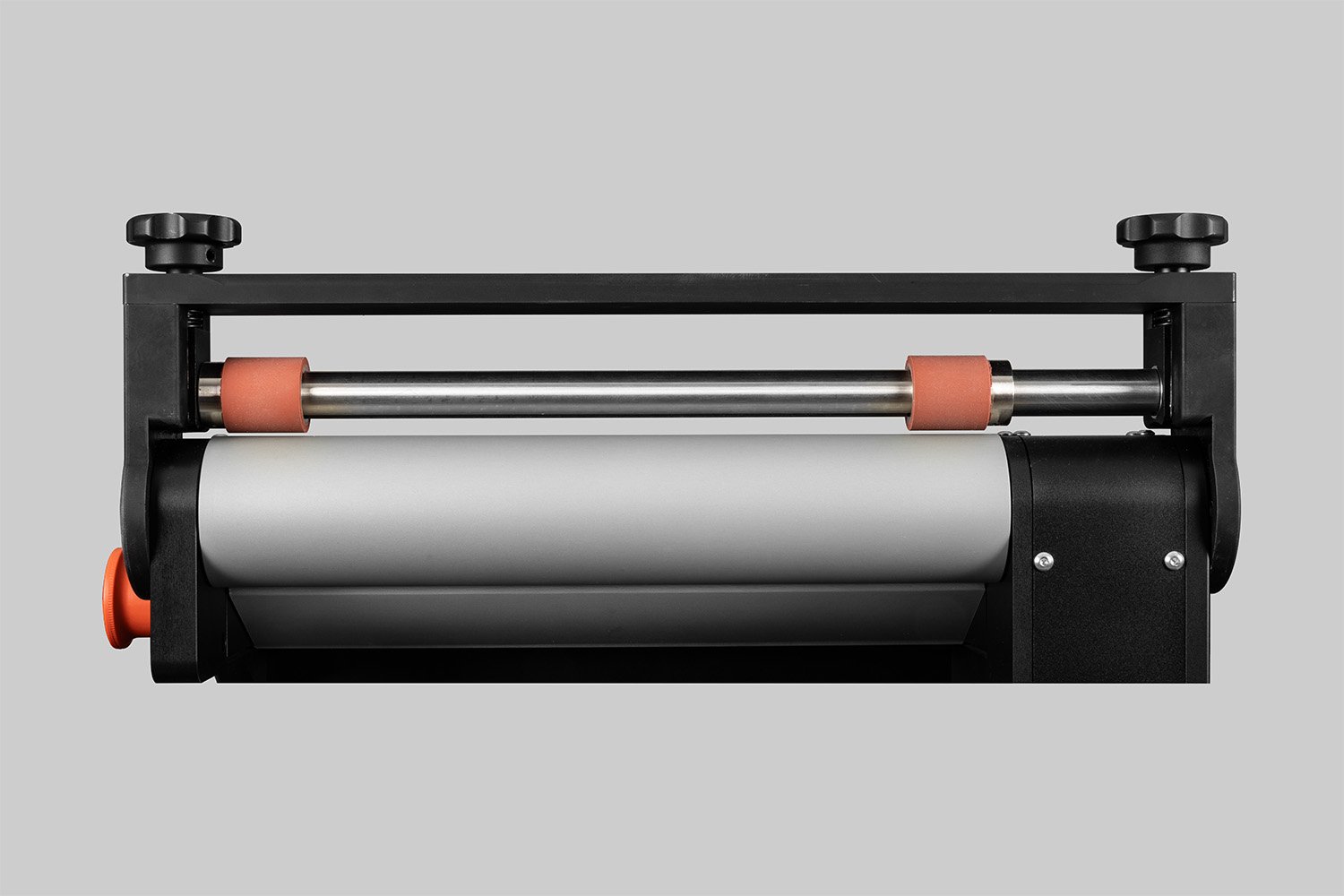

The Laboratory Roll-to-Roll Coater includes a versatile nip mechanism before the rewinder, available in various configurations. This mechanism presses the web against the roller, enhancing web movement and speed control. The basic setup has a full rubber roller with manual nip pressure and tilt control. Advanced versions offer adjustable nip rollers and automated control of nip engagement, pressure, and pressure points. It can also serve as a simple laminator for easy manual packaging of devices.

The nip roller enhances web control by pressing the web onto the roller, increasing friction and optimizing web movement and speed. Includes both manual control of nip pressure and tilt.

Roller for adjustable nip and two nip rollers with 30 mm width.

8. Rollers

The standard Laboratory Roll-to-Roll Coater features 60 mm diameter anodized aluminum rollers, crucial for your system's performance. These durable and cost-efficient rollers are ideal for 95% of applications, offering low runout and some electrical insulation. For specific needs, we also provide POM rollers (black or white) for better contrast, PEEK rollers for extreme chemical resistance, and stainless steel rollers for maximum corrosion resistance.

In the standard configuration, the Laboratory Roll-to-Roll Coater is equipped with high-quality anodized aluminum rollers, each with a diameter of 60 mm. For specialized needs, we also offer rollers in POM (available in black or white for contrast), PEEK (for exceptional chemical resistance), and stainless steel (for extreme corrosion resistance).

10. Get a Quotation

Congratulations on customizing your Laboratory Roll-to-Roll Coater! You are now ready to receive a quotation. If you are uncertain about your platform or component choices, please contact us. We’d be delighted to assist you.