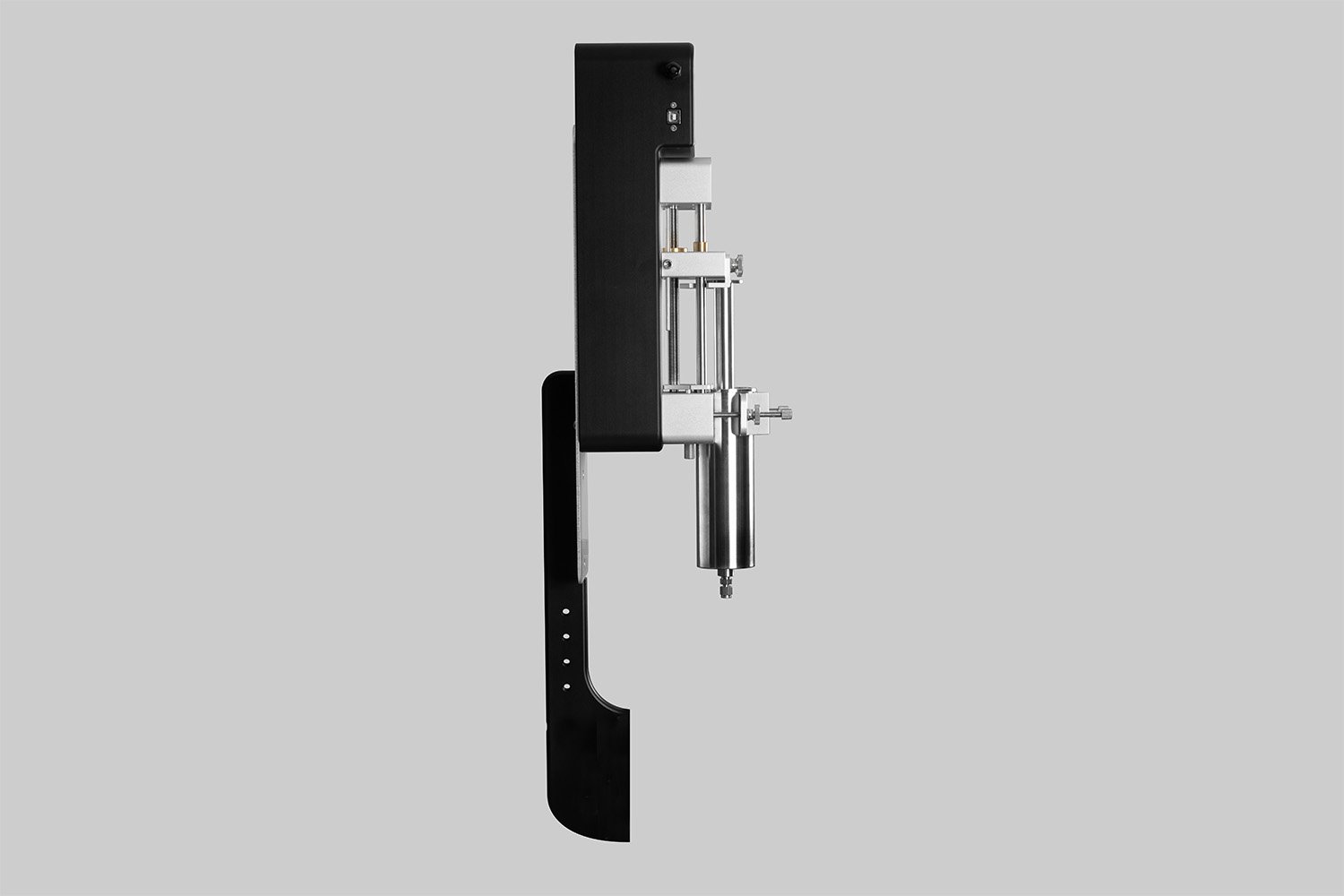

Introducing the Mammoth Syringe Pump: Precision and Power for High-Volume Coating Applications

At infinityPV, we are excited to unveil the Mammoth Syringe Pump, designed specifically for the Laboratory Roll-to-Roll Coater. Built to handle the high demands of high-volume coating applications, the Mammoth Syringe Pump sets a new standard in precision and versatility. Whether you're working with inks, battery slurries, or other fluidic materials, the Mammoth Syringe Pump ensures consistent, reliable, and precise fluid delivery, making it an indispensable part of your advanced coating processes.

Unmatched Precision for High-Volume Coating Applications

The Mammoth Syringe Pump features a robust 300 ml stainless steel syringe, offering exceptional durability to withstand even the most challenging materials. Corrosive fluids are no match for its stainless steel construction, and its simple design ensures easy cleaning and maintenance, ensuring minimal downtime. This high-performance pump is perfect for applications where consistency in coating thickness is critical, such as printed electronics, battery manufacturing, and solar cell development.

Key Features:

Precision Flow Control: Guarantees consistent coating thickness and material distribution.

Versatile Material Compatibility: Suitable for a wide range of materials, including low-viscosity inks and dense battery slurries.

Durable Stainless Steel Design: Corrosion-resistant and long-lasting for extended use in demanding environments.

User-Friendly Interface: The 5-inch touchscreen simplifies programming, monitoring, and fine-tuning.

Multi-Pump Operation: Allows multiple pumps to work in tandem, enhancing process flexibility and efficiency.

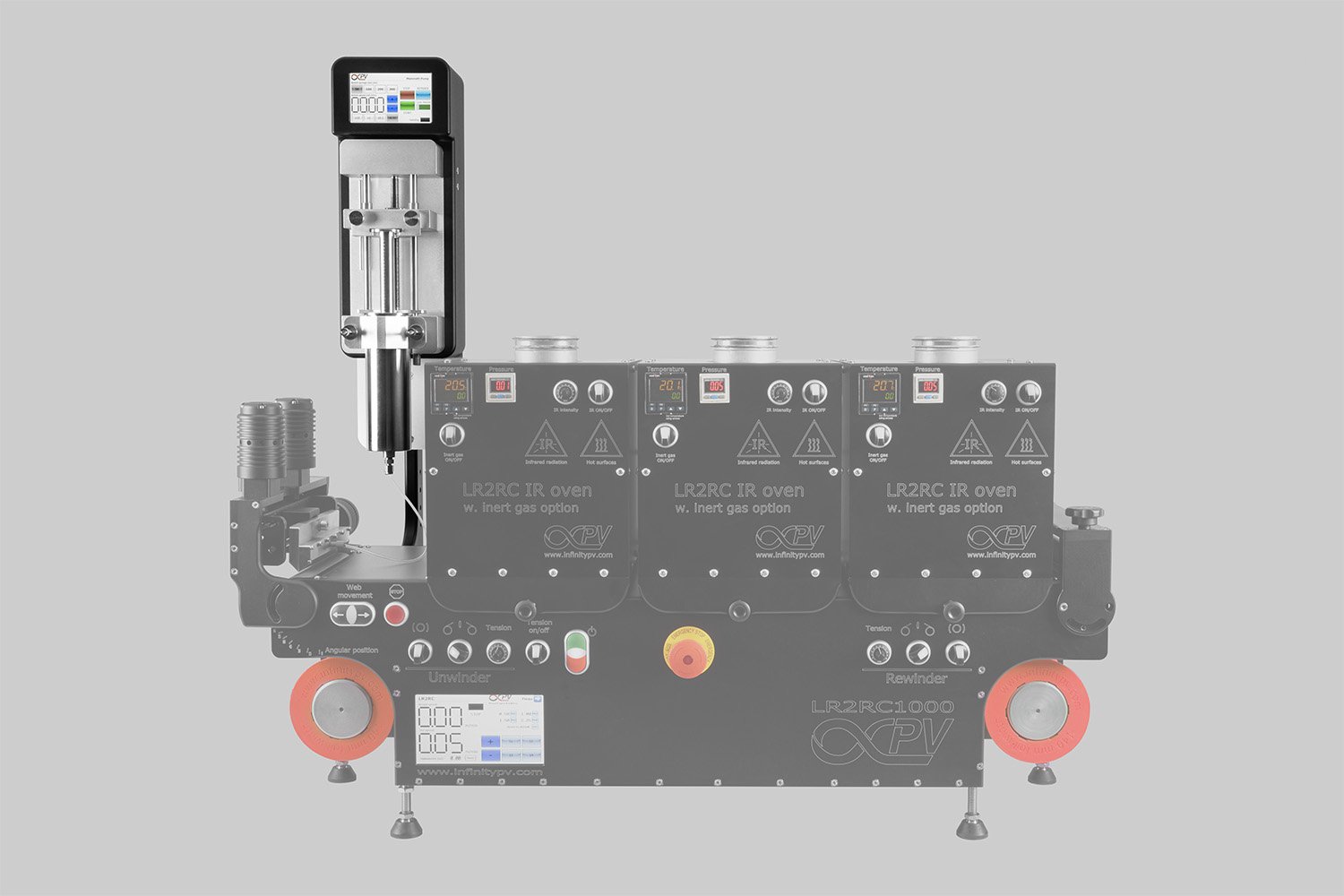

Integration with LR2RC: Seamless integration with the Laboratory Roll-to-Roll Coater ensures optimized workflows for coating, laminating, and drying.

The Mammoth Syringe Pump offers the ideal solution for research labs and industrial setups looking to take their coating processes to the next level with precision and reliability.

Other infinityPV Pumps: The Jumbo Syringe Pump and Gear Pump

While the Mammoth Syringe Pump offers unmatched precision for high-volume applications, infinityPV also offers two other innovative pumps designed to meet the needs of diverse coating and fluid dispensing applications.

Jumbo Syringe Pump

The Jumbo Syringe Pump is specifically designed for high-volume roll-to-roll (R2R) manufacturing processes, including slot-die coating. With a range from 0-60 ml, the Jumbo Syringe Pump provides accurate ink delivery for both small-scale and high-volume setups. Its 5-inch touchscreen interface and USB computer connectivity make it easy to control and monitor, ensuring precision in the delivery of inks and slurries.

The Jumbo Syringe Pump is available in multi-pump configurations for complex experiments and production processes, offering gradient and dilution protocols with ease. Whether you're working with sheet or roll coating, the Jumbo Syringe Pump is a versatile choice for your needs.

Key Features:

5" Color Touchscreen for easy operation

Multi-pump capabilities for complex fluid delivery

USB Interface for seamless data logging

Free software for enhanced control

Compatibility with the Laboratory Roll-to-Roll Coater and Research Laboratory Coater

Gear Pump

The Gear Pump is a high-performance positive displacement pump, ideal for handling a broad range of fluids with precision. Perfect for both low and high flow rate applications, the Gear Pump is well-suited for use in slot-die coating systems, particularly for non-Newtonian fluids like pastes, inks, and slurries.

With a wide viscosity range and low pulsation delivery, the Gear Pump offers precise ink dosage, ensuring accuracy in coating processes. It also features a 5-inch touchscreen for easy control and configuration, with a USB interface for data logging and integration into advanced workflows.

Key Features:

Flow Rate Range: 0.05 ml/min to 288 ml/min

High Dosage Precision with a CV < 1% at low volumes

Corrosion-Resistant Construction suitable for harsh chemicals

Adjustable Flow Rate via RPM control

Compatible with Laboratory Roll-to-Roll Coater: Ideal for a variety of slot-die coating applications

Find the Right Pump for Your Application

Whether you need the Mammoth Syringe Pump for high-volume coating, the Jumbo Syringe Pump for large-scale production, or the Gear Pump for precise fluid delivery across diverse applications, infinityPV has you covered. All three pumps integrate seamlessly with the Laboratory Roll-to-Roll Coater, offering flexible solutions to meet the specific needs of your slot-die coating and other fluid-based processes.

Explore the possibilities and elevate your coating precision with infinityPV's innovative pump solutions. Contact us today to learn more about the Mammoth Syringe Pump and other pump options to optimize your research and production.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

Research Laboratory Coater

A versatile, compact system for producing high-quality films using multiple deposition techniques like slot-die coating and flexo.