RealNano

In-line and Real-time Nano-characterization Technologies for the High Yield Manufacturing of Flexible Organic Electronics

Project Description

RealNano is funded by the European Union's HORIZON 2020 research and innovation programme and is an ambitious 36-month project that will develop novel and fast real-time nano-characterization materials tools & methodologies based on Spectroscopic Ellipsometry, Raman Spectroscopy, Imaging Photoluminescence and Laser Beam Induced Current Mapping that will be integrated to in-line R2R (Roll-to-Roll) Printing and OVPD (Organic Vapor Phase Deposition) Pilot-to-Production Lines (PPLs) for characterization of Organic & Printed Electronics (OE) nanolayers, devices & products during their manufacturing.

Main Objectives:

Develop rapid and real-time nanoscale, multi- modal & scale characterization tools/methodologies for OEs

Integrate the non-destructive nano-characterization tools in in-line R2R printing and OVPD Pilot to Production Lines

Develop characterization protocols and Data Management for interoperability across industries

Demonstrate the tools in industrial OE processes for improvement of quality and reliability of products

Validation of OE product quality and manufacturability on commercial applications

Effective Transfer of results to industry by Open Innovation (Dissemination, Training, Networking/Clustering) and Management

The above can be only addressed by a European approach and a transnational cooperation between excellent entities in characterization/modelling and industrial entities with unique pilot lines. This project will bring together academic, SME and industrial partners with world-class excellence and established track-record in metrology tools and manufacturing. This project will have a huge impact and will transform the manufacturing processes for Organic Electronics Industry and for other Industries as Thin Films (e.g. functional films, antimicrobial and decoration coatings, barriers), Electronics, Wearables, Energy, Automotive, Transport, Space, Health, etc.

Partners

Coatema

Centro Ricerche Fiat

APEVA

About RealNano

Organic/Large Area Electronics (OLAE) is a rapidly emerging sector, that combines organic, polymer, inorganic and hybrid materials in multilayer nano-structures for large-scale manufacturing of conformable & lightweight devices for energy harvesting (OPV) and light emission (OLED for lighting). Their conformability and capability for large area manufacturing can enable their widespread implementation in existing and new consumer products from energy, lighting, displays and surfaces, electronic circuits, all (bio) sensors, wearables, ICT, IoT, etc.

In order to unleash the huge potential of OPVs and OLEDs in consumer applications and to enable Industrial Growth in Europe, it is crucial to achieve fast OLAE-enabled product delivery with an unprecedented yield and quality. Also, their manufacturing processes must demonstrate a strong productivity improvement to remain commercially competitive.

However, there are several challenges to address that include: insufficient control of the properties of materials and devices, inhomogeneities in their thickness, structure over large areas, low process yield, limited reliability and high consumption of resources, batch-to-batch and run-to-run variations in properties and performance, increased waste and high costs. These delay significantly the market acceptance of OLAE-enabled products.

Organic and Large Area Electronics (OEs) is one of the most rapidly emerging sectors of the Nano Science and Technology, that revolutionizes many industrial applications in (Lighting & Displays, Energy, Buildings, Transport, Photonics, Health, Wearables, IoT, etc) and developed in parallel with the R2R Printing and Vapour Phase Deposition Technologies for its products manufacturing. The OE market is rapidly growing worldwide, from 31.7 B$ in 2018 to 77.3 B$ in 2029 driven by OLEDs, OPVs, biosensors, flexible batteries. OEs is a huge opportunity for EU industry to become a global leader in this field.

However, the wider commercialization of OEs requires the implementation of process-adapted, fast, accurate and robust nanoscale analytical tools that could offer reliable quality control of materials/devices and cost effective fabrication.

RealNano will solve these bottlenecks by developing a novel combination of multimodal, multi-scale, non-destructive and truly fast in-line and real-time nano-characterization tools, and smart modelling methodologies to revolutionize manufacturing of OEs.

The RealNano innovations will open the way to revolutionize industrial manufacturing of OEs for numerous industrial applications, by:

Large Area Printing Technologies (R2R, Sheet-to-Sheet) for the large area manufacturing of polymer-based OEs composed of ultra-thin nanolayer architectures in complex OE products (OPV, OLED, OTFTs, etc.) for applications in Automotive, Energy, Packaging, Electronics, Wearables, Health, etc. Gas Transport & Vapour Deposition Technologies (OVPD, PVD, CVD, ALD) for fabrication of advanced OE nanolayers (inorganic, organic, hybrid, nanoparticles) and devices with superior quality and reproducibility in structure, surface/interface quality and performance.

Related Pages

Customer Success Stories

Dive into our clients' success stories! Check out what they're saying about our services and how we've made a difference in their journeys.

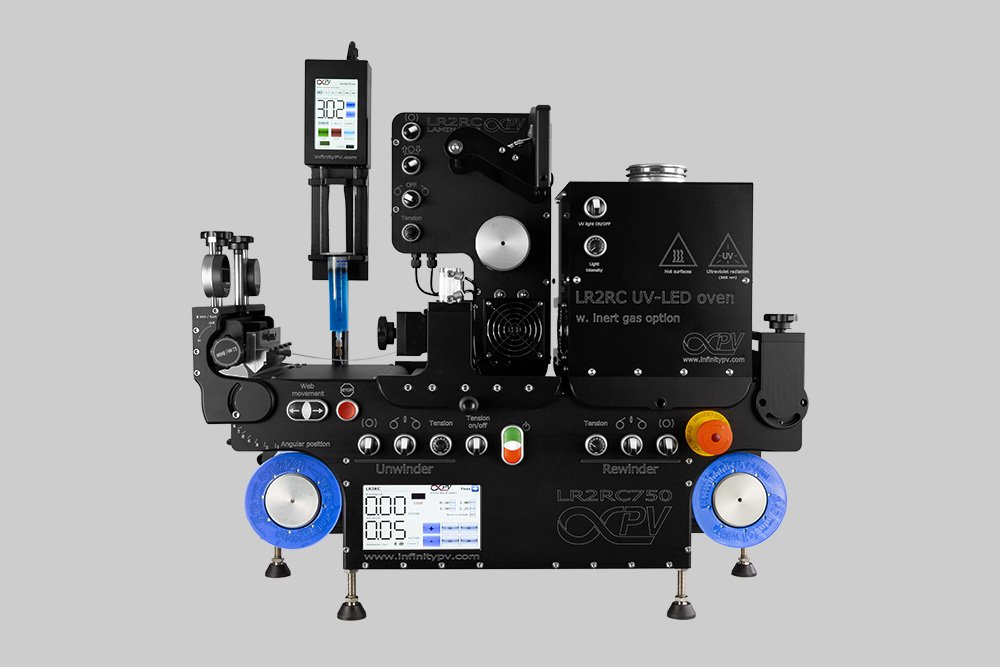

Products

Discover our turnkey platforms for efficient printed electronics manufacturing, including batteries, solar cells, and sensors.