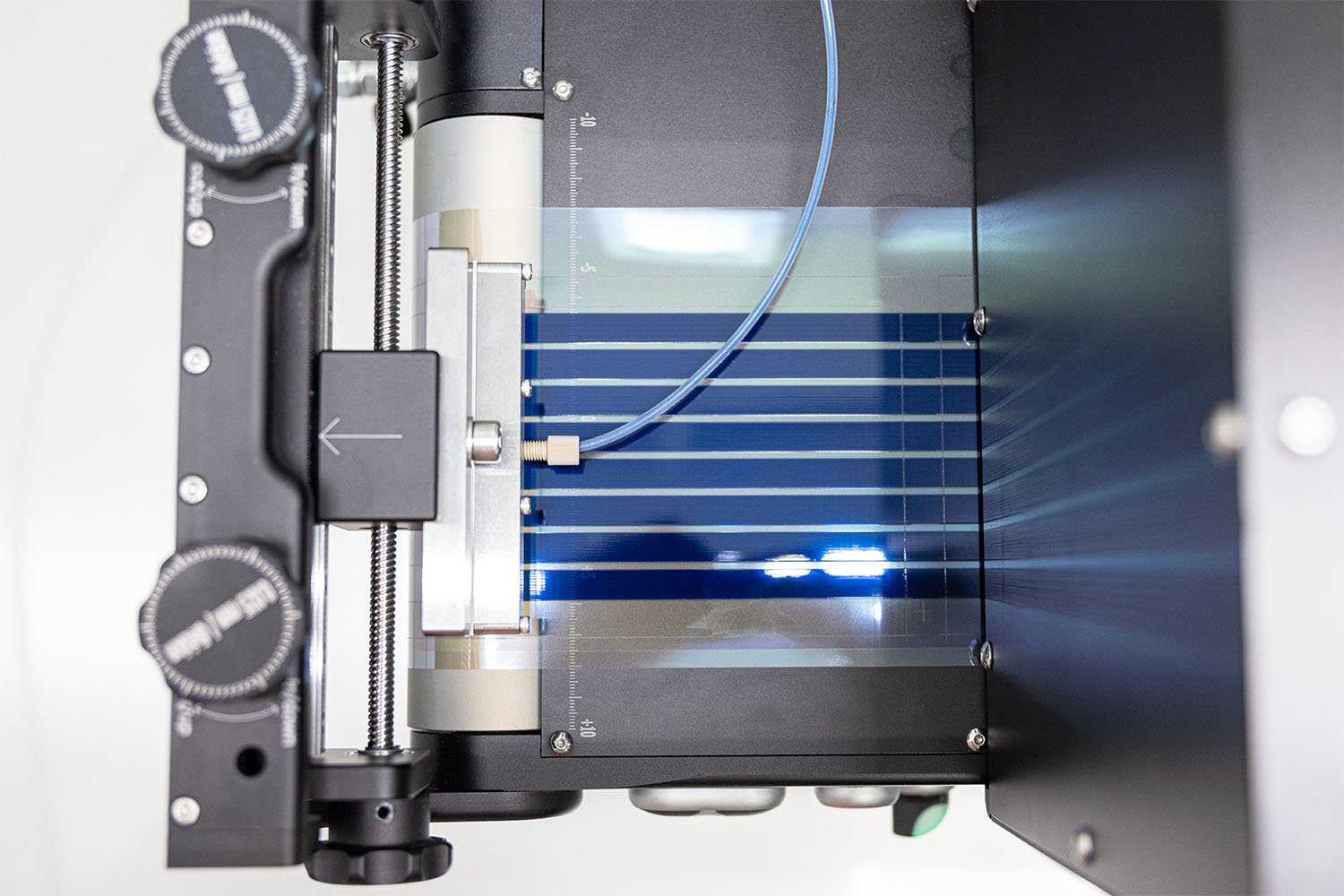

Image 1 of 12

Image 1 of 12

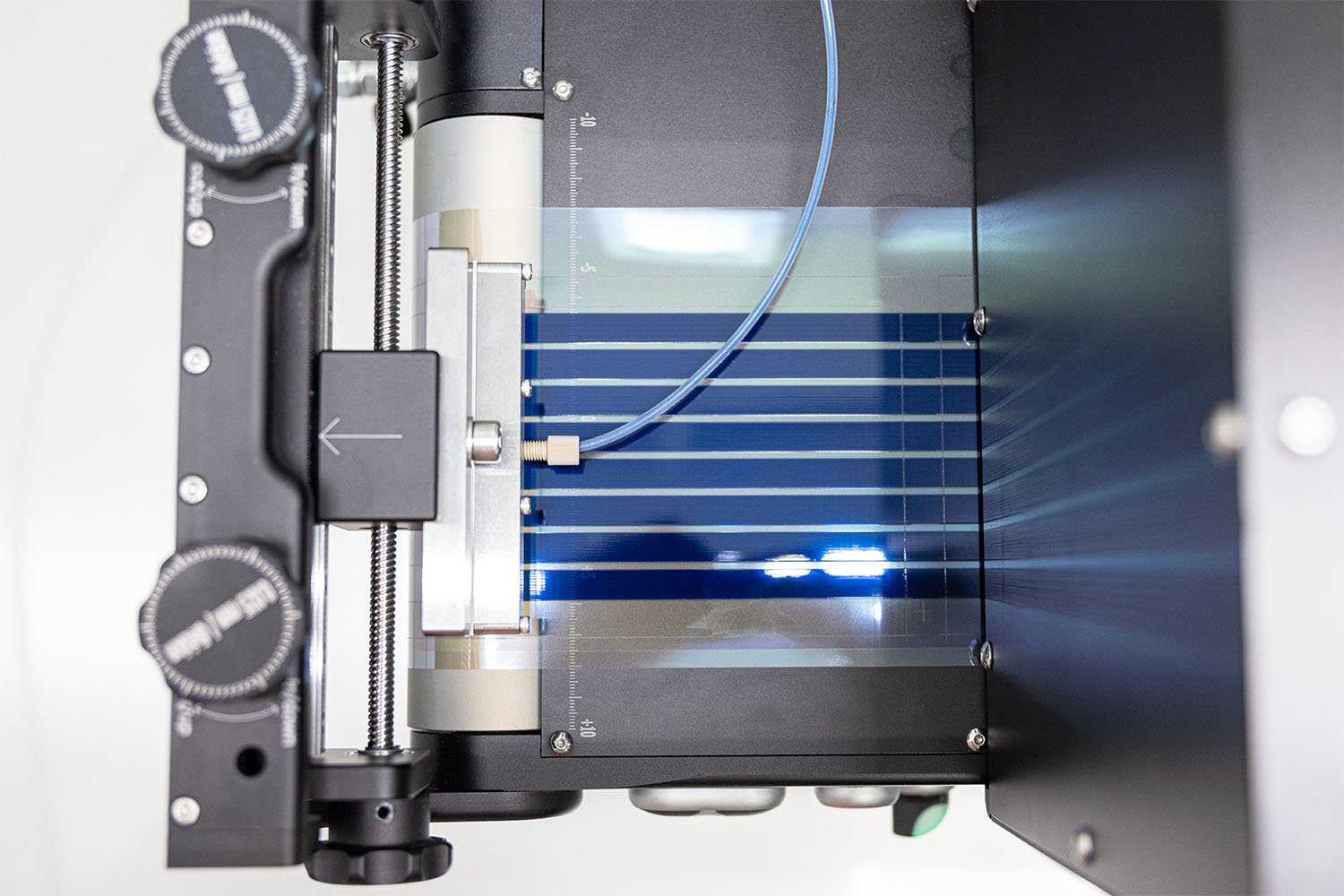

Image 2 of 12

Image 2 of 12

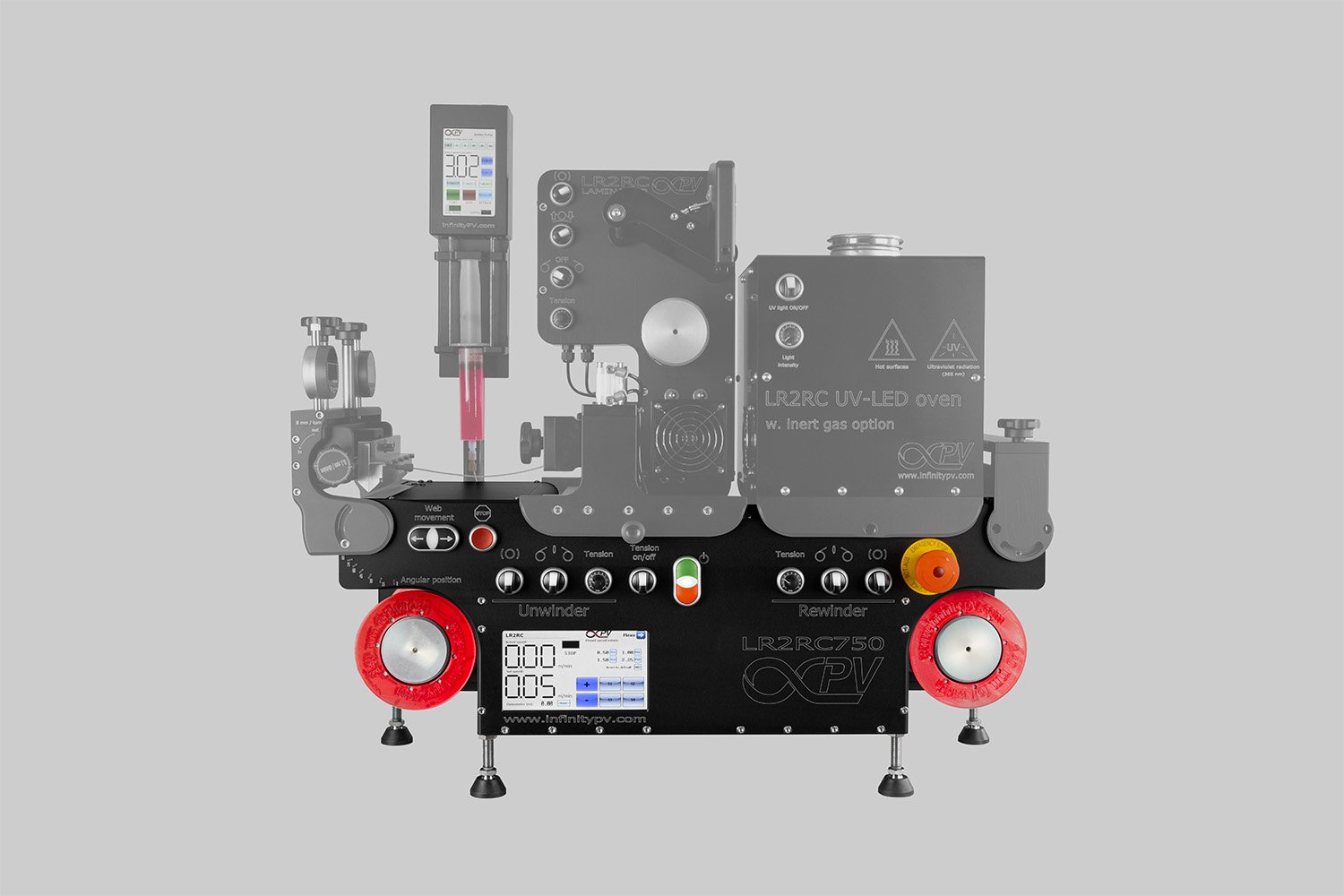

Image 3 of 12

Image 3 of 12

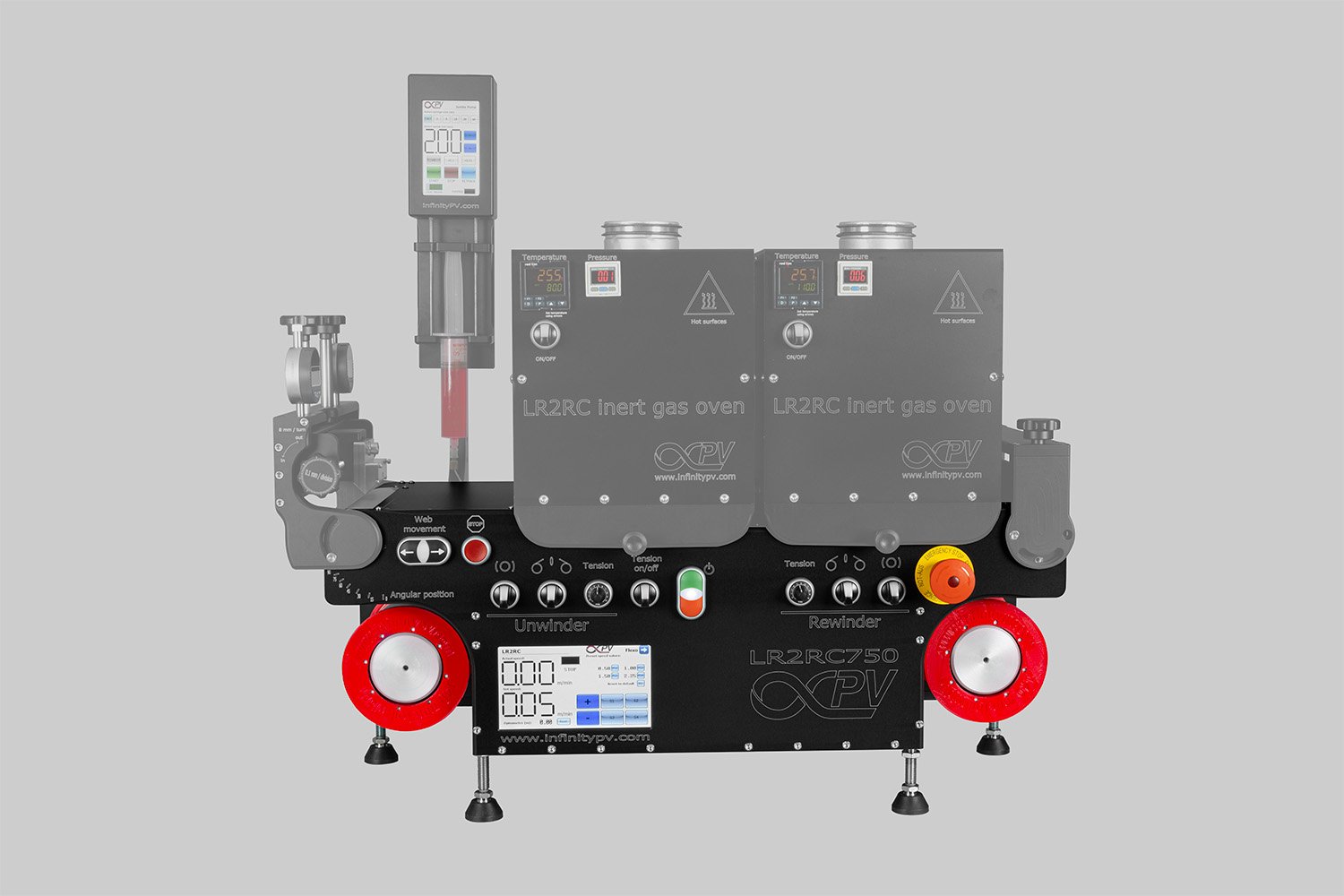

Image 4 of 12

Image 4 of 12

Image 5 of 12

Image 5 of 12

Image 6 of 12

Image 6 of 12

Image 7 of 12

Image 7 of 12

Image 8 of 12

Image 8 of 12

Image 9 of 12

Image 9 of 12

Image 10 of 12

Image 10 of 12

Image 11 of 12

Image 11 of 12

Image 12 of 12

Image 12 of 12

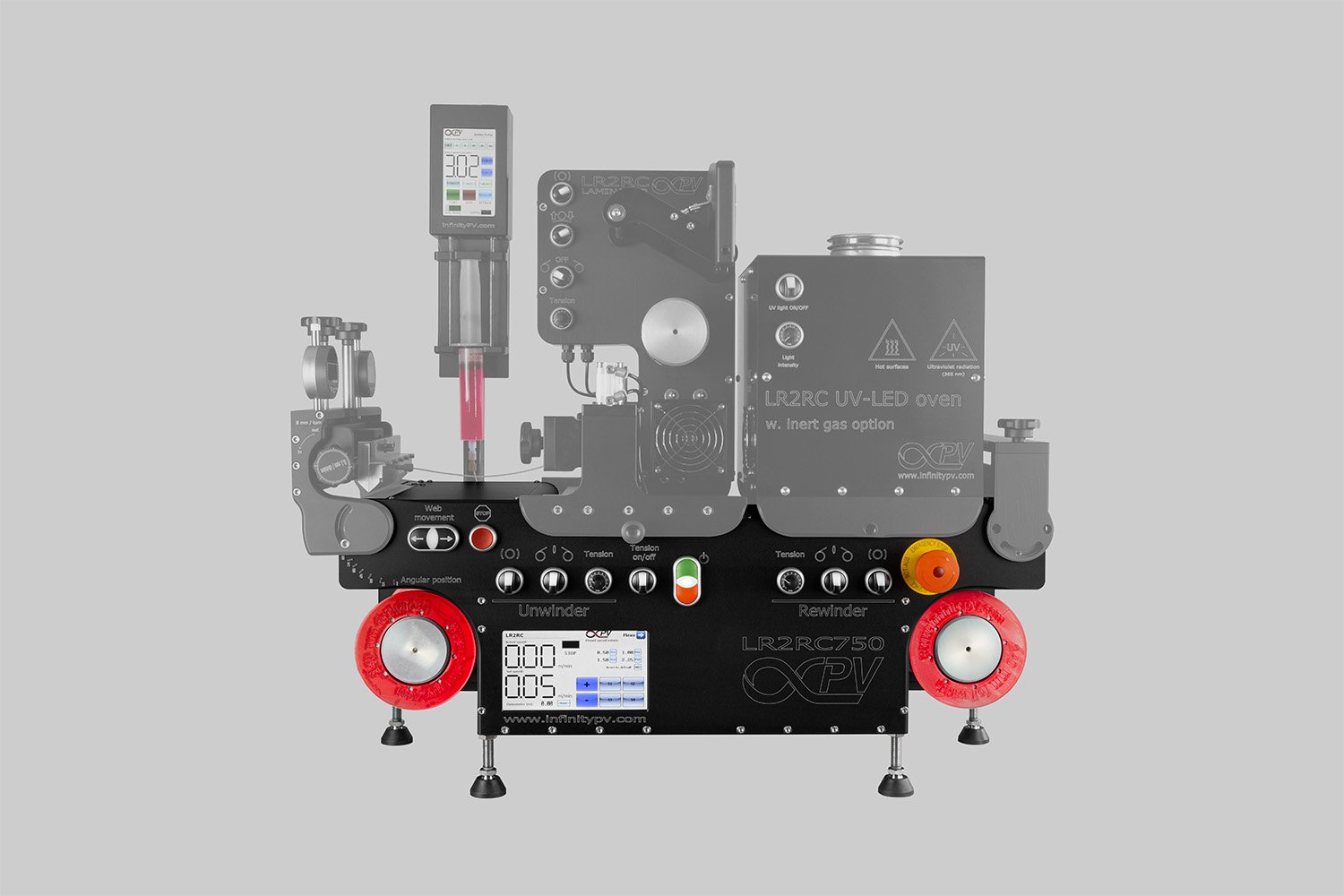

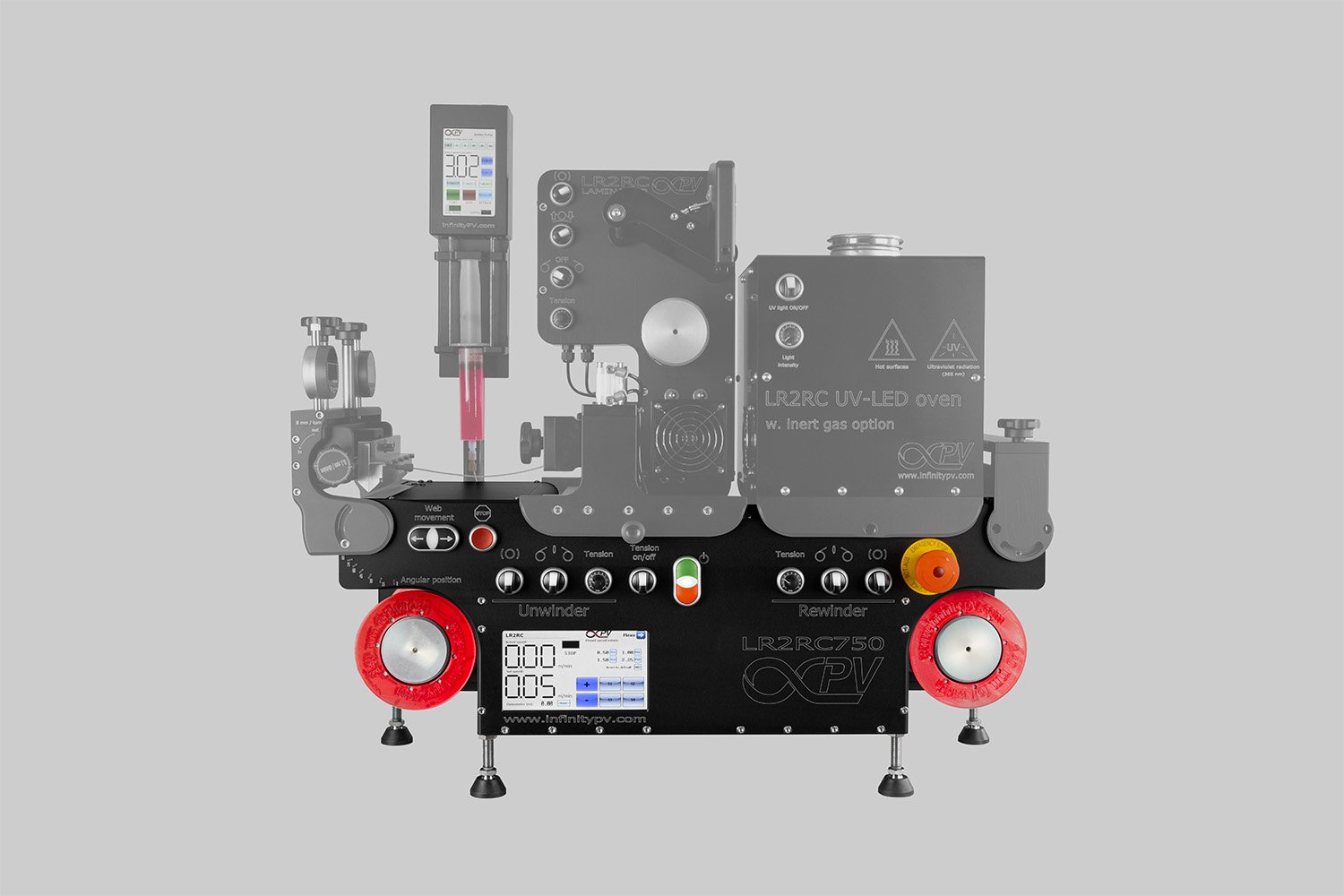

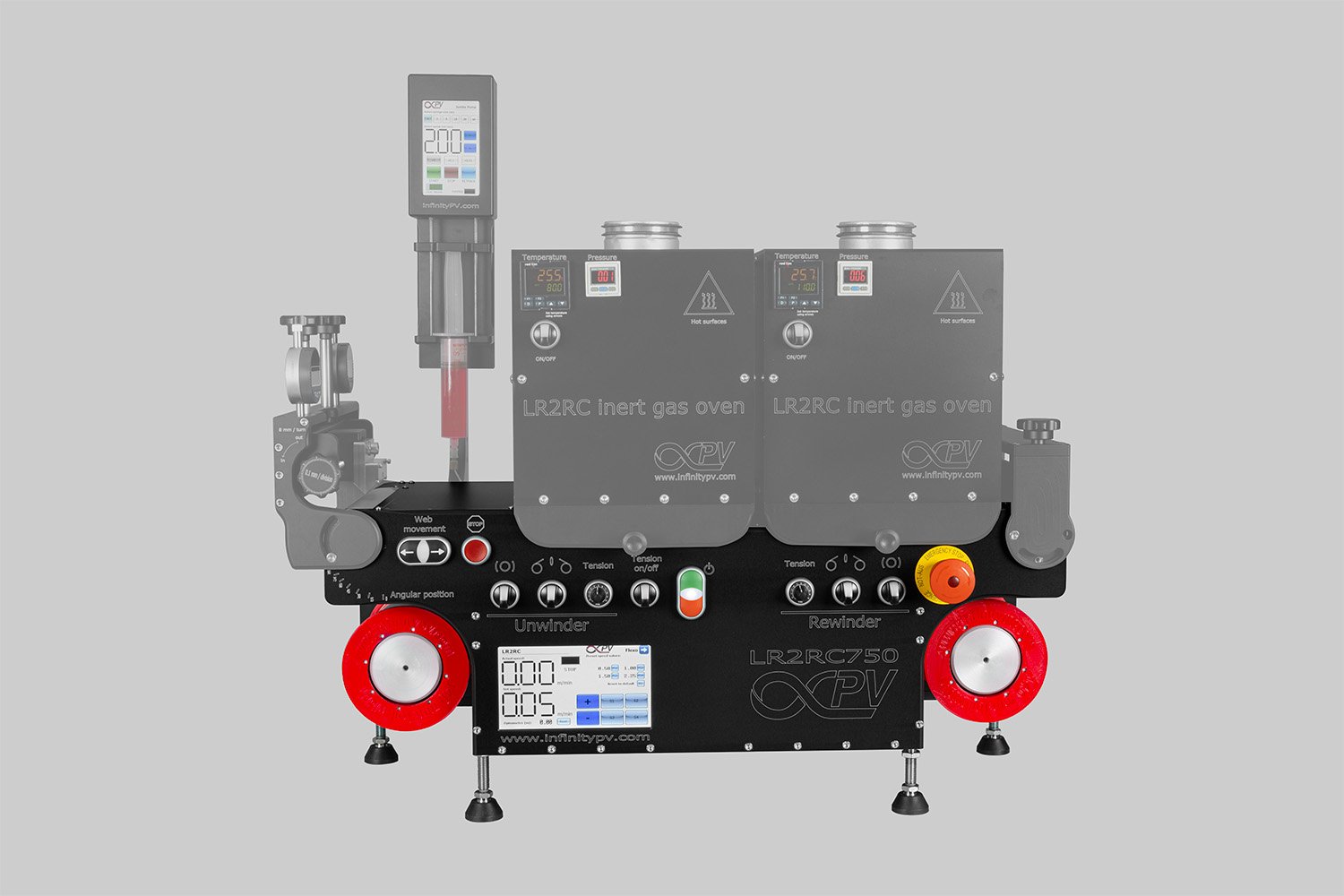

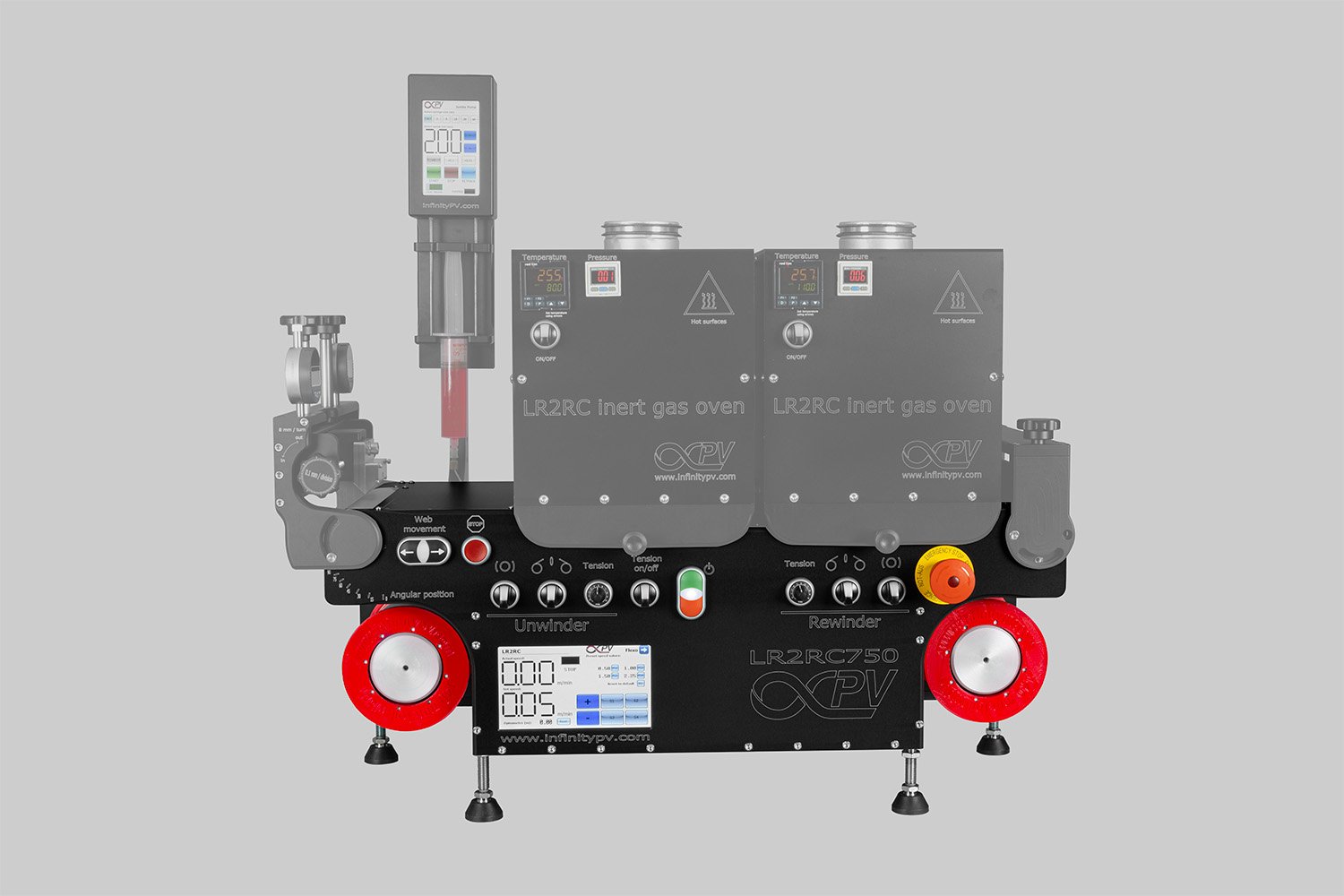

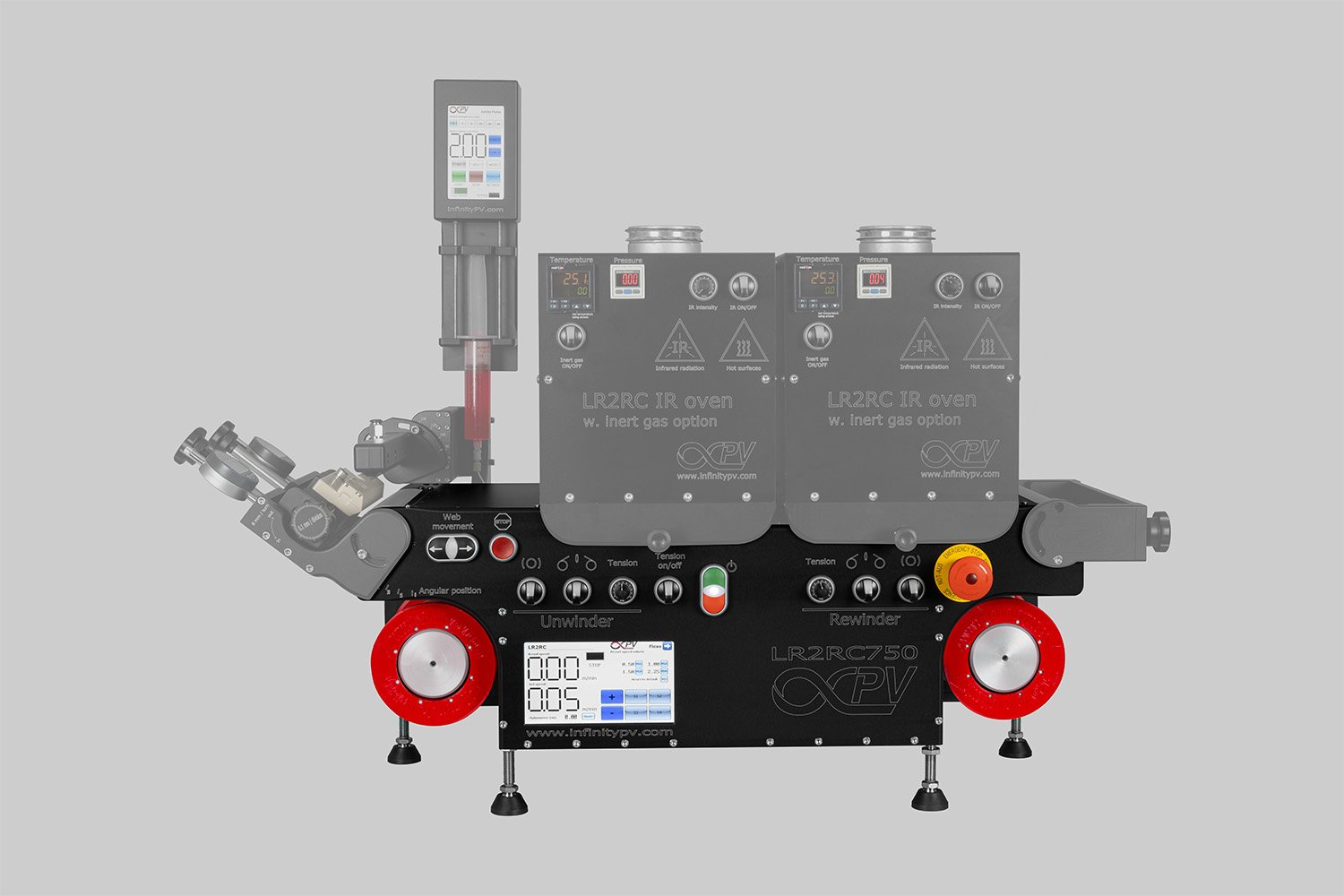

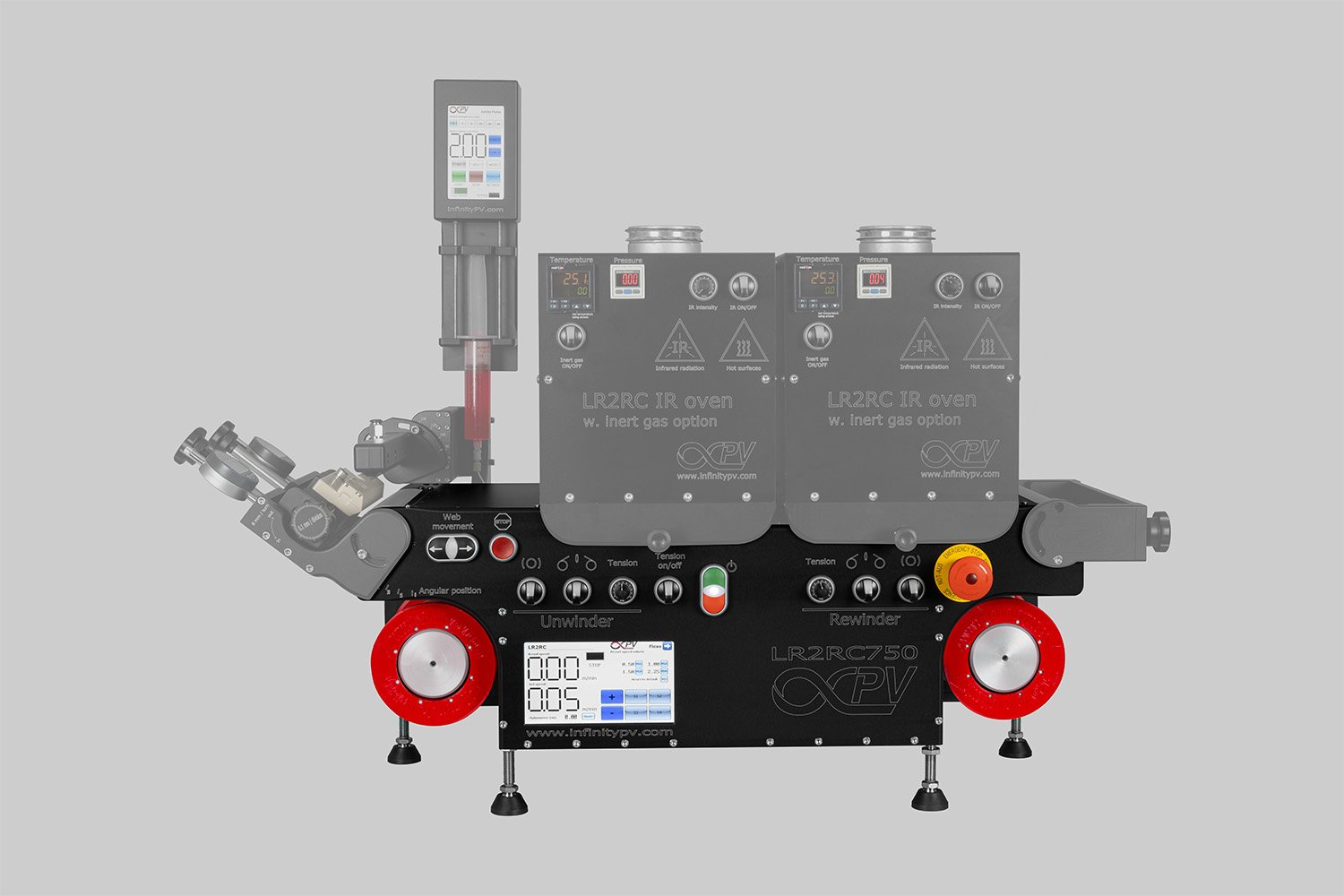

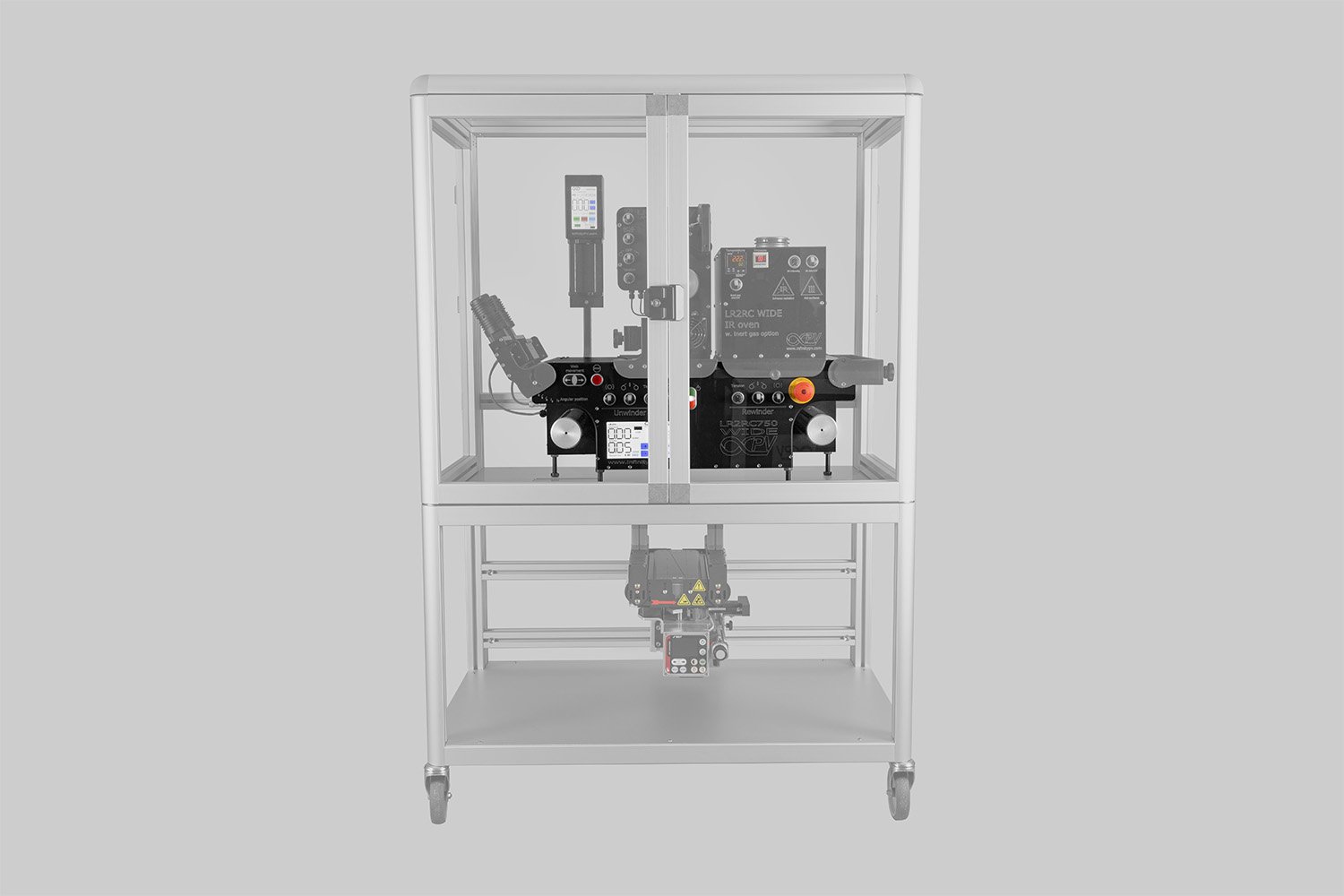

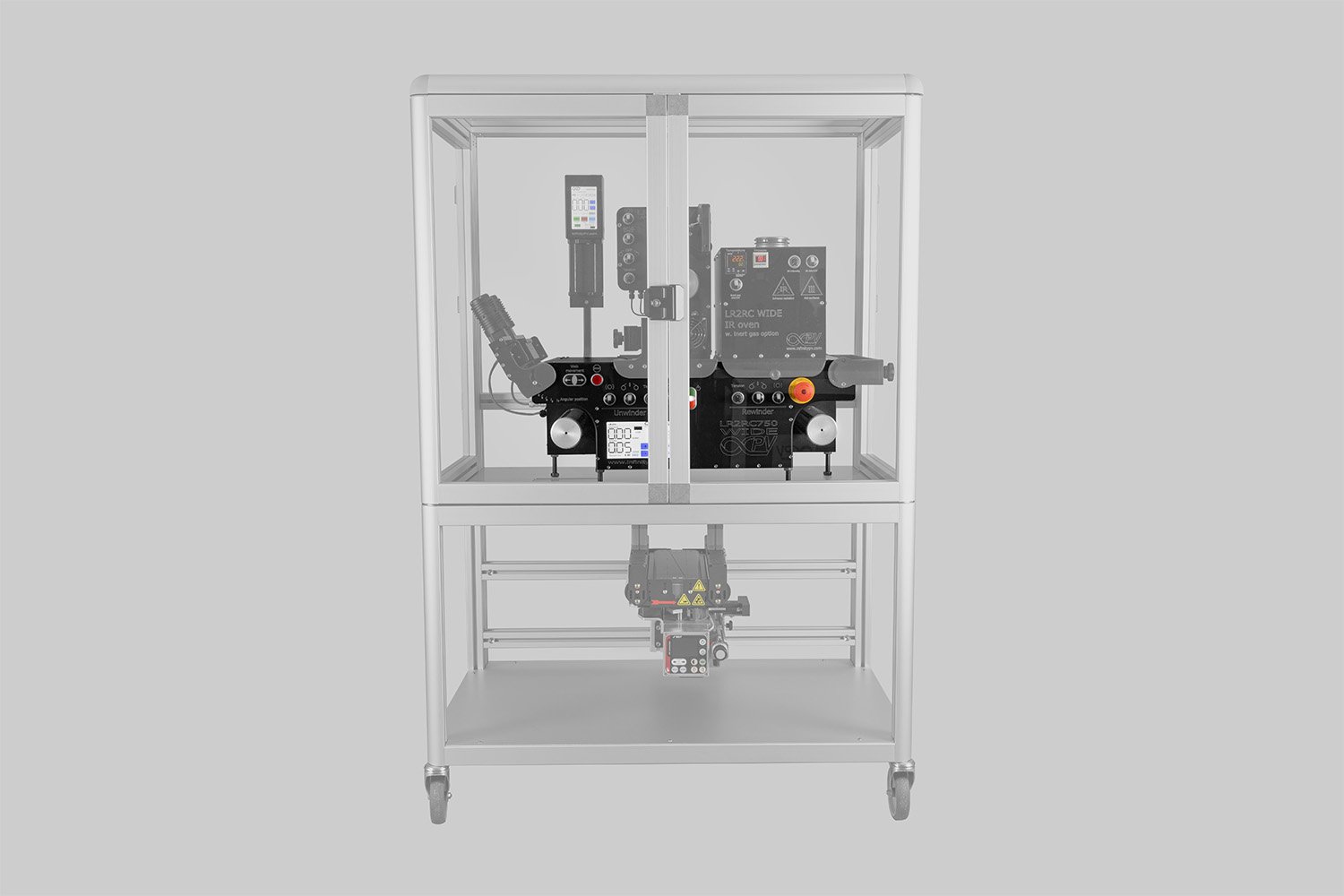

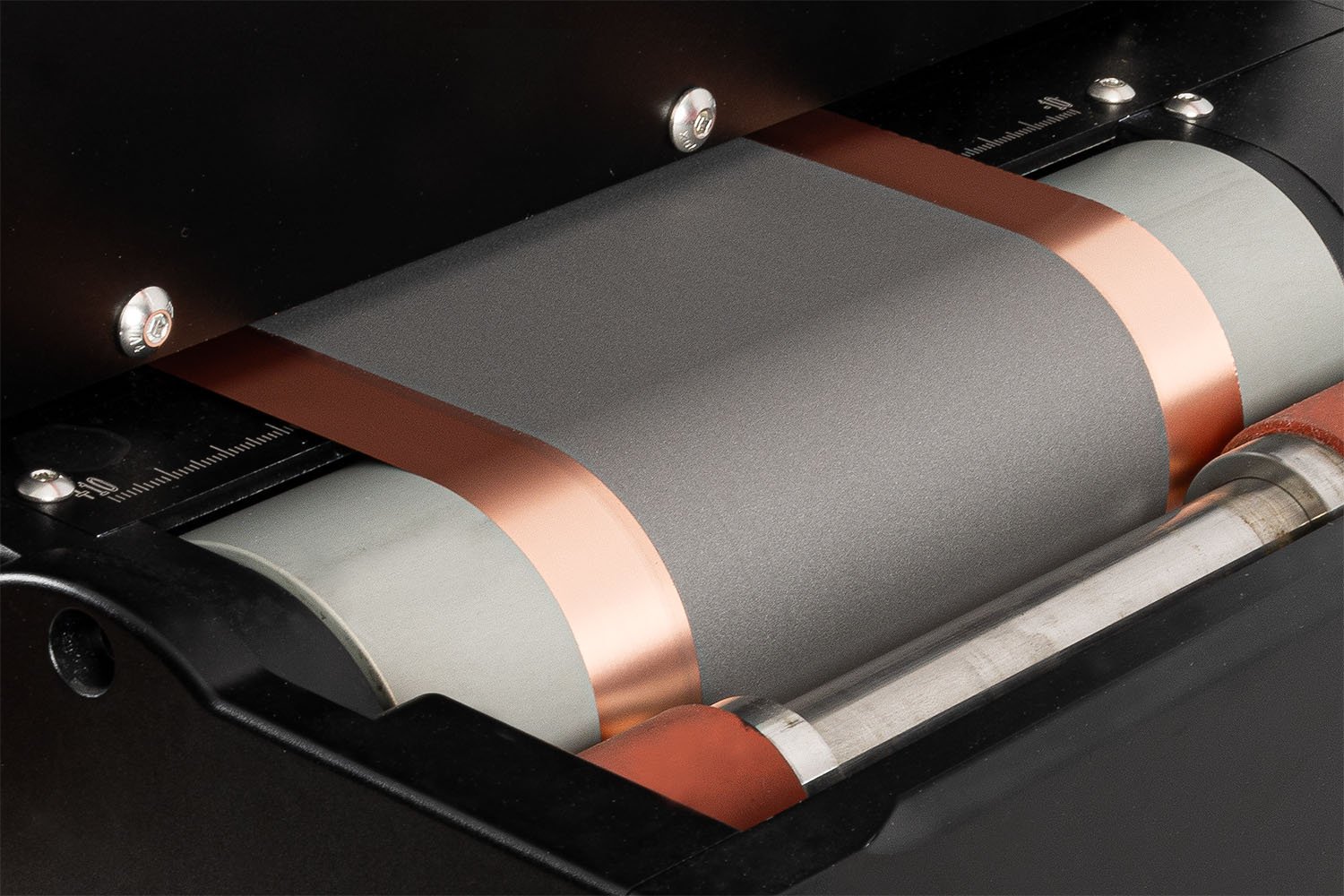

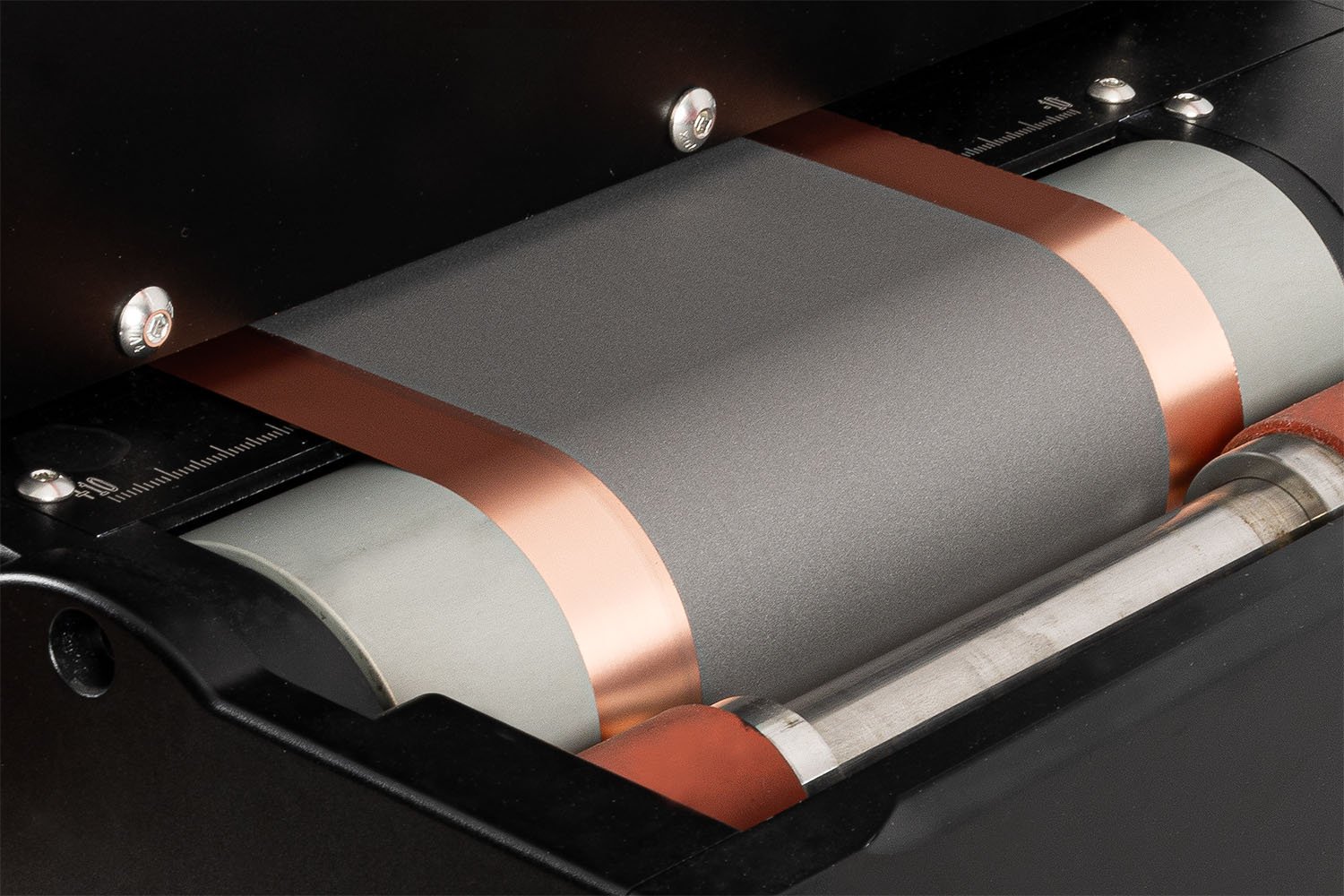

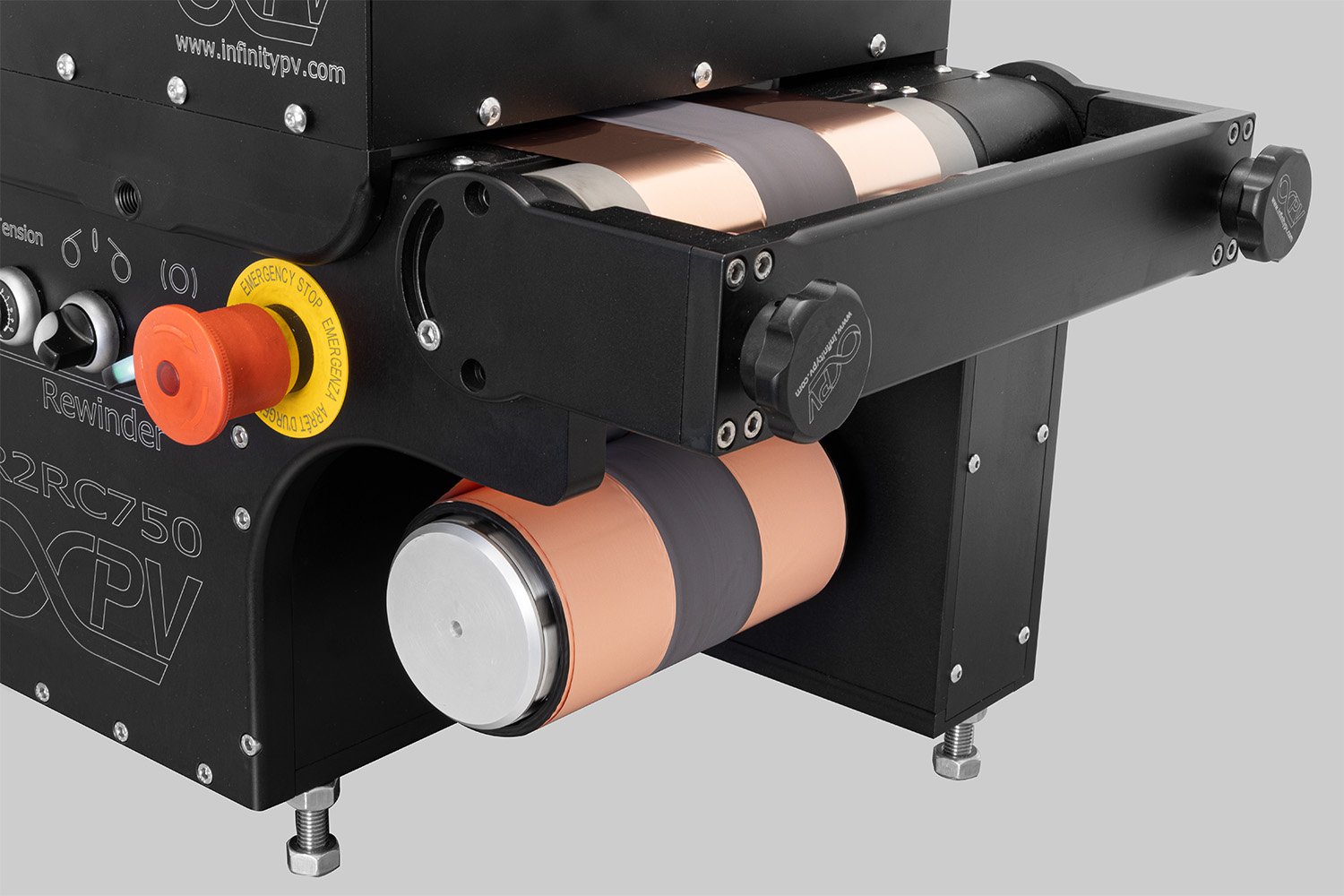

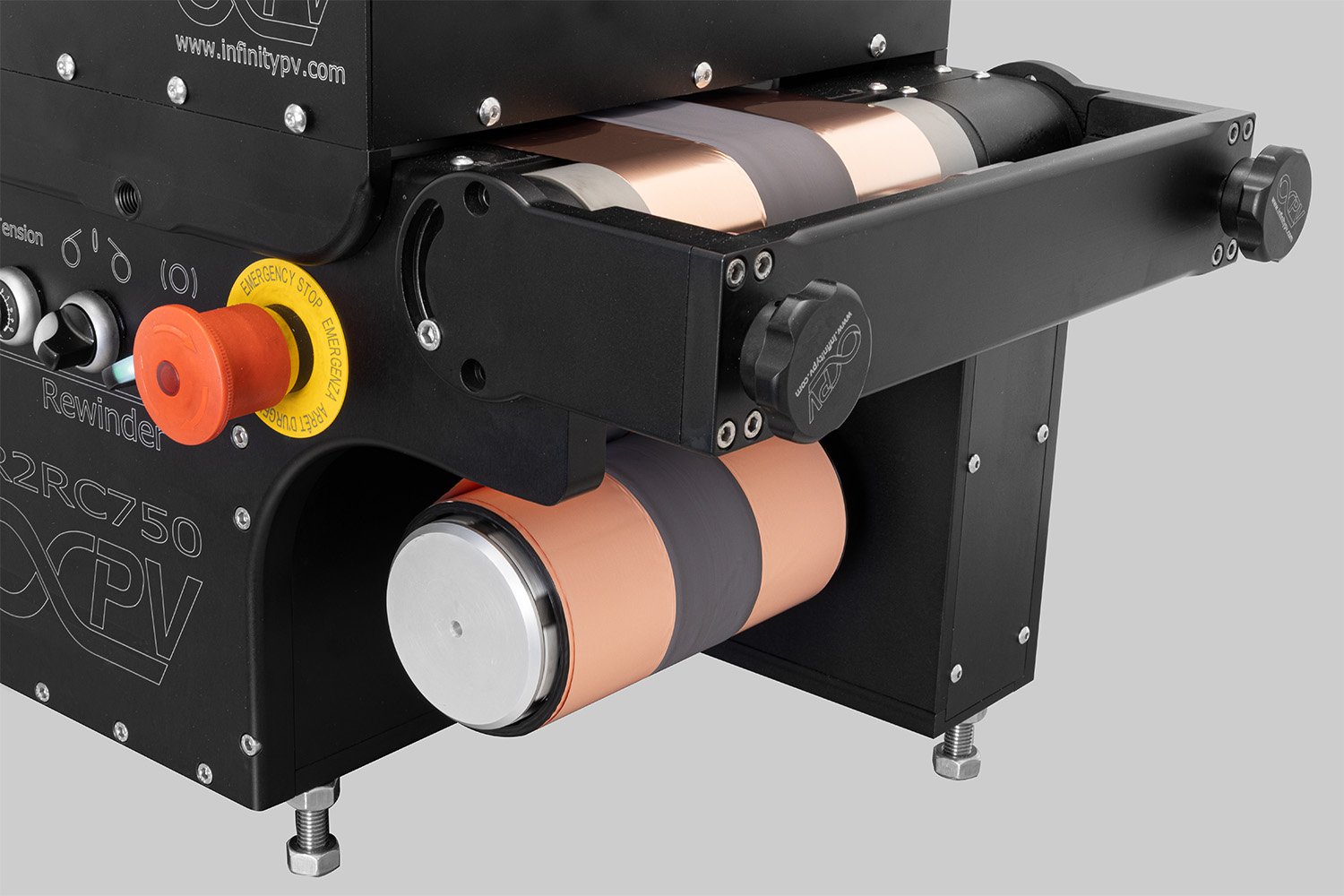

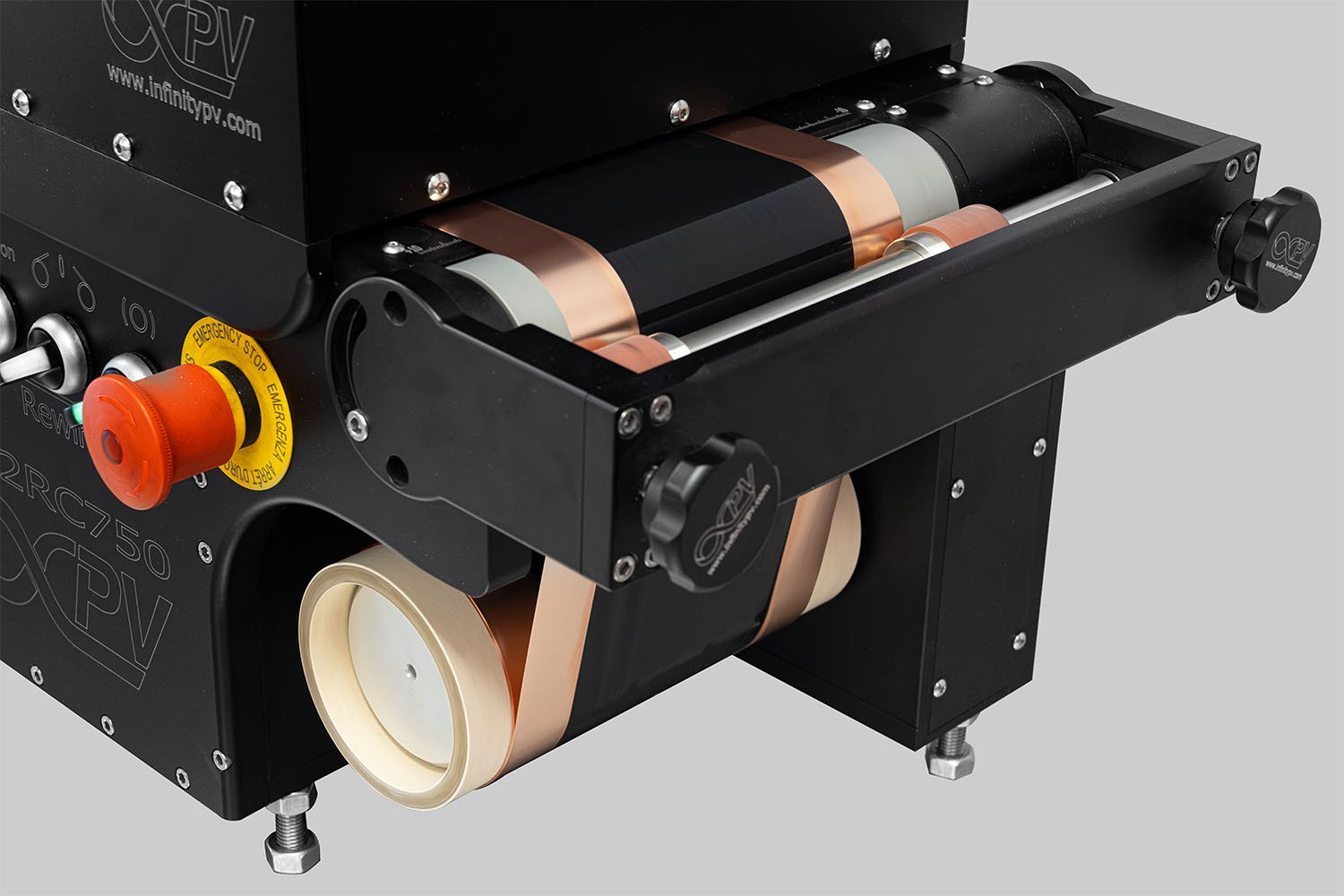

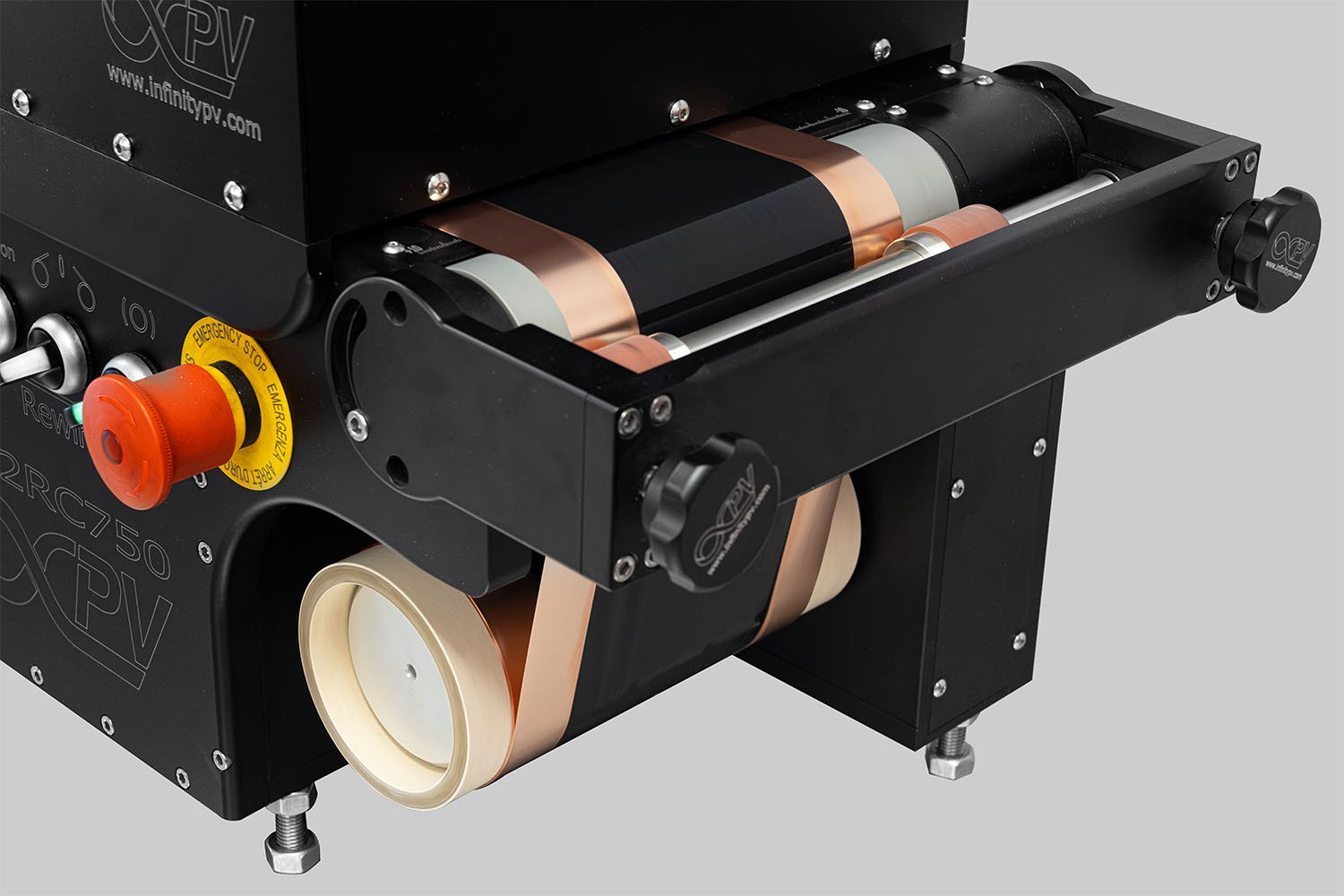

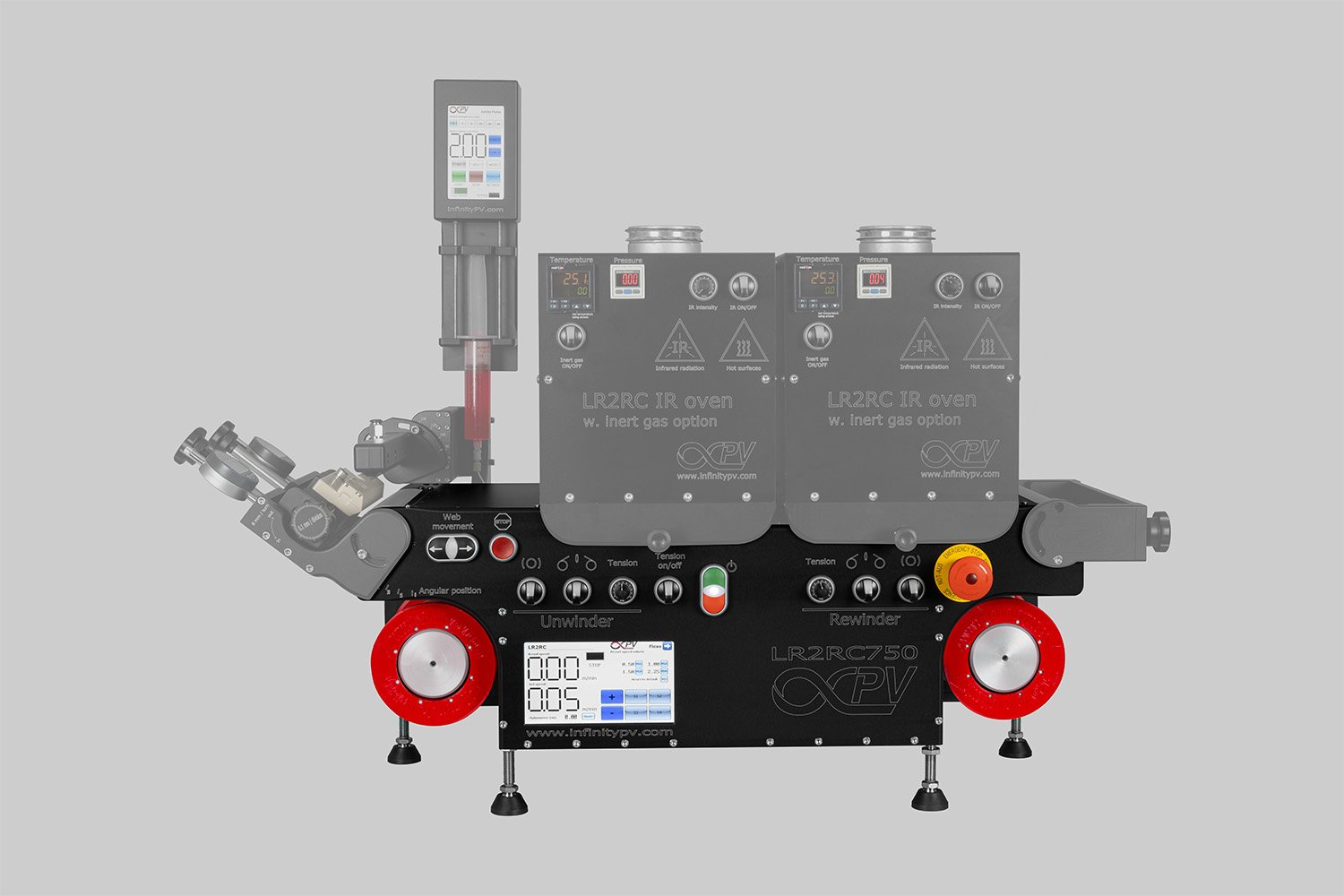

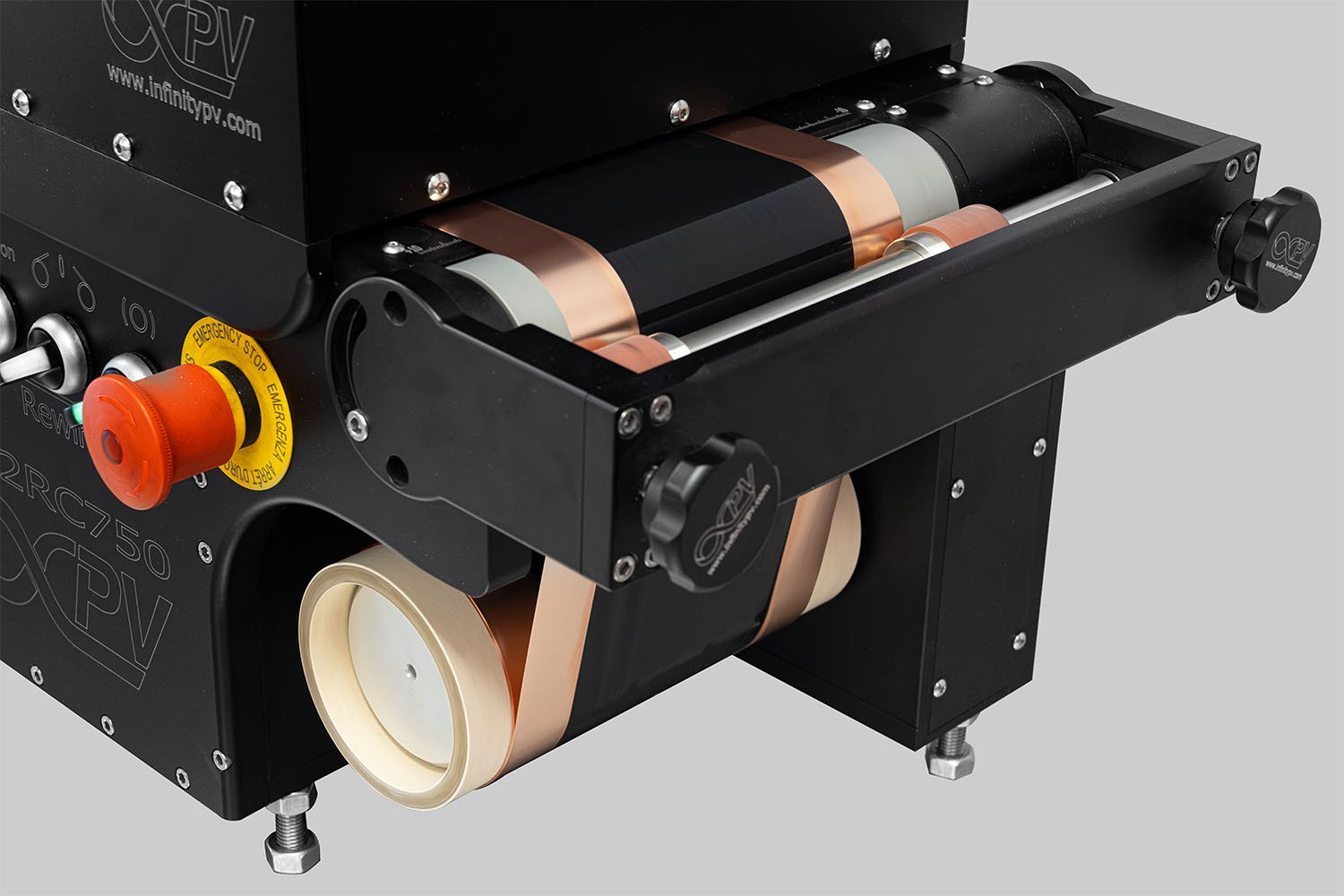

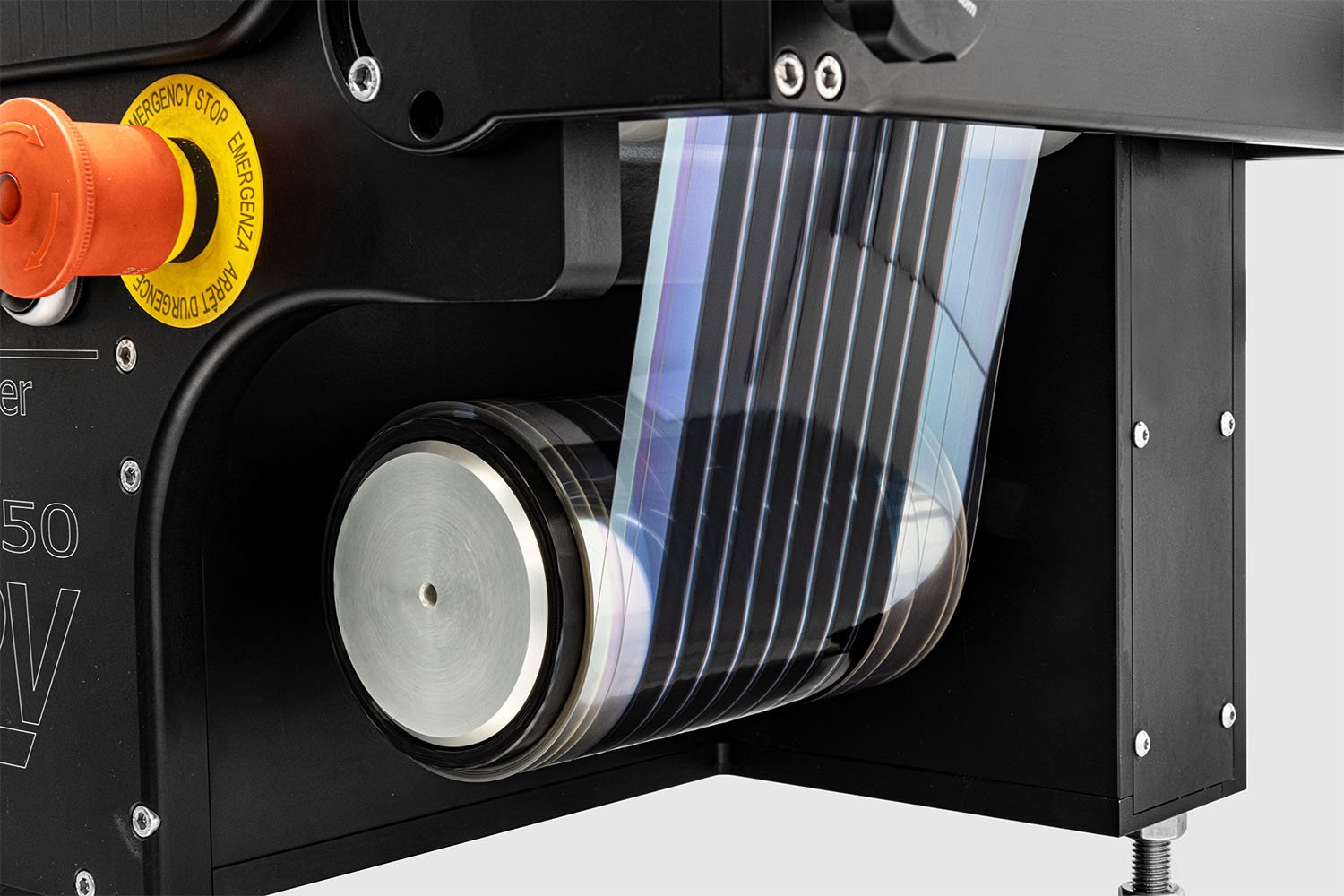

LR2RC750 Platform

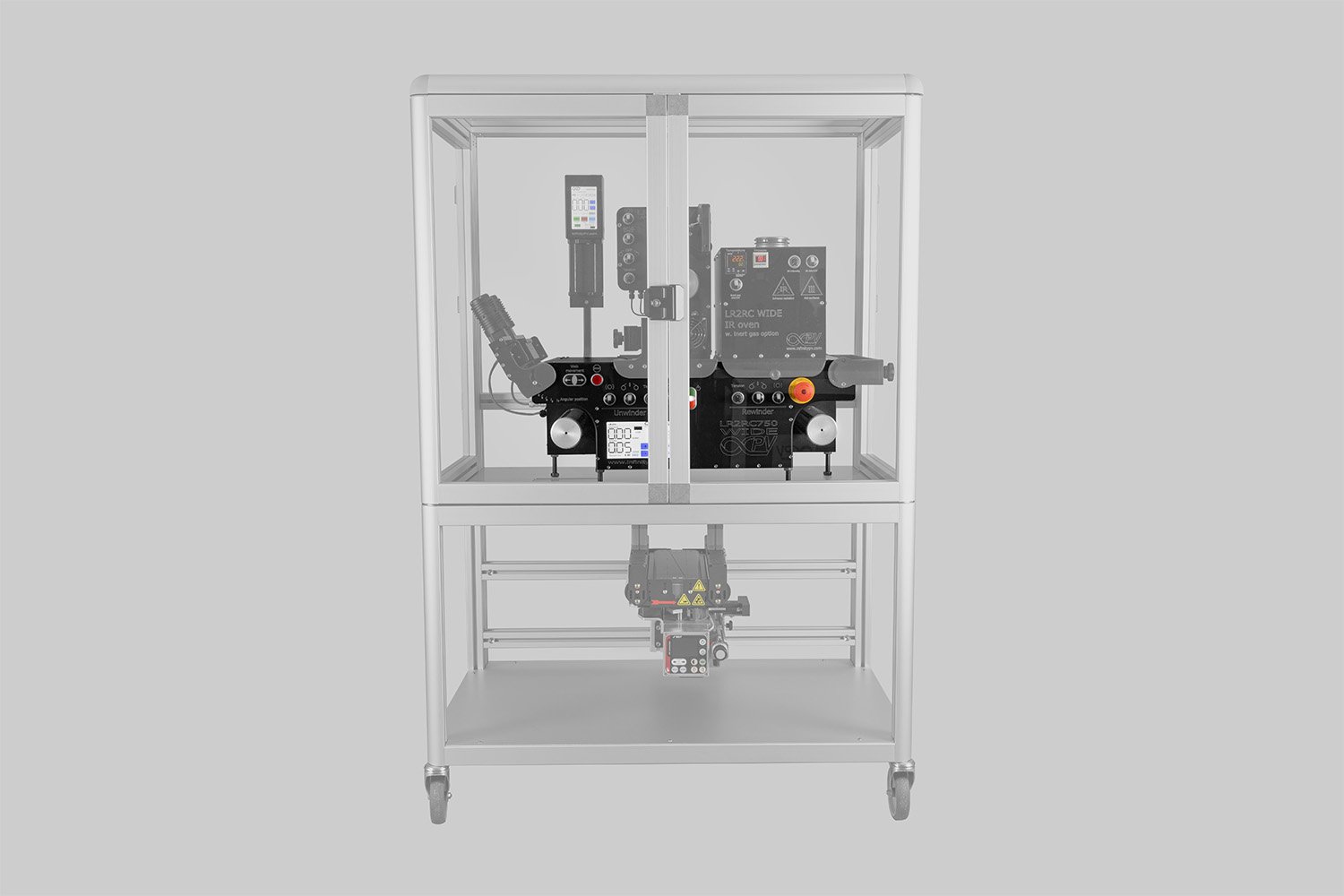

Finding the ideal balance between size and functionality, the LR2RC750 seamlessly accommodates additional features while remaining a perfect fit for fume hoods or gloveboxes.

Finding the ideal balance between size and functionality, the LR2RC750 seamlessly accommodates additional features while remaining a perfect fit for fume hoods or gloveboxes.

Finding the ideal balance between size and functionality, the LR2RC750 seamlessly accommodates additional features while remaining a perfect fit for fume hoods or gloveboxes.

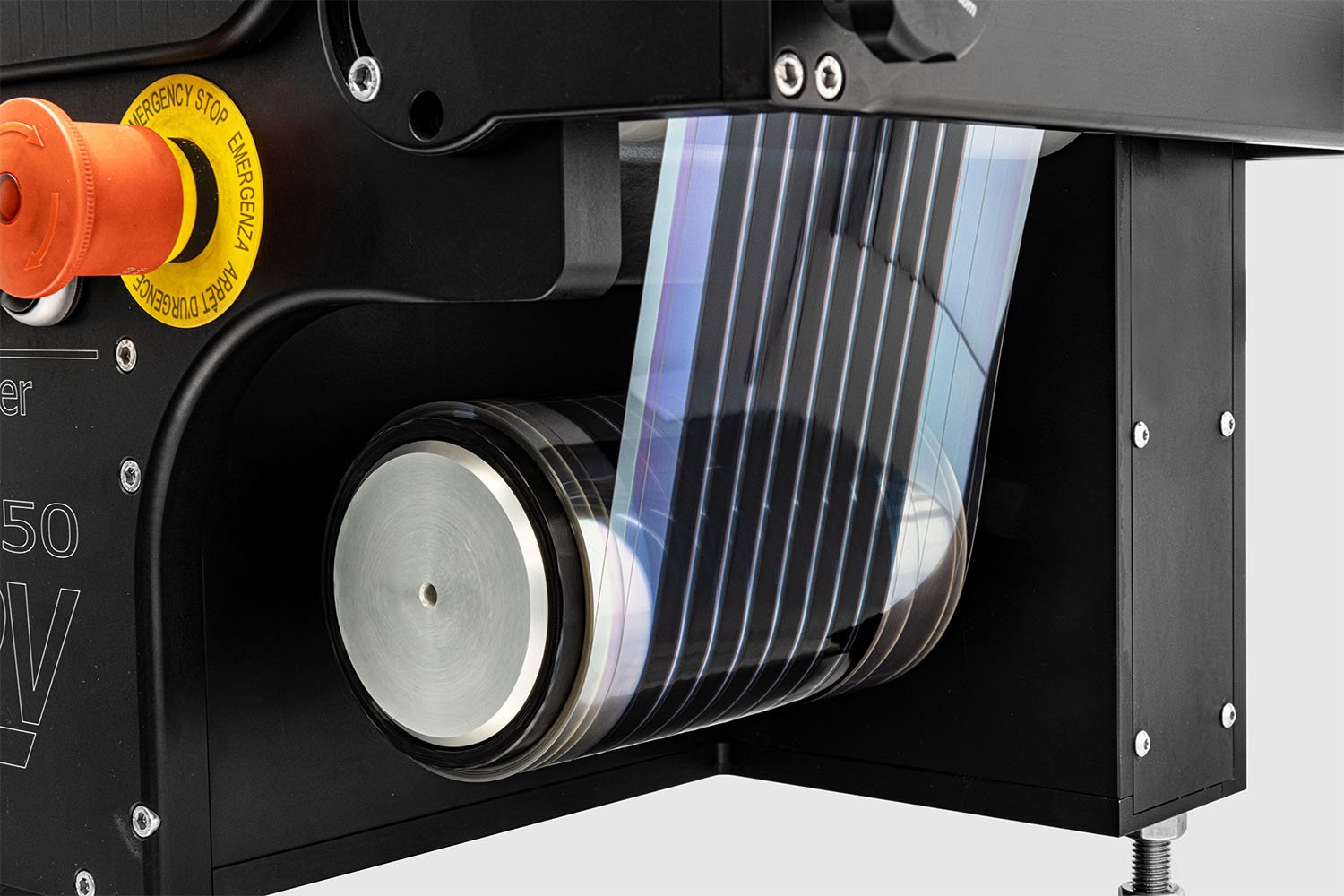

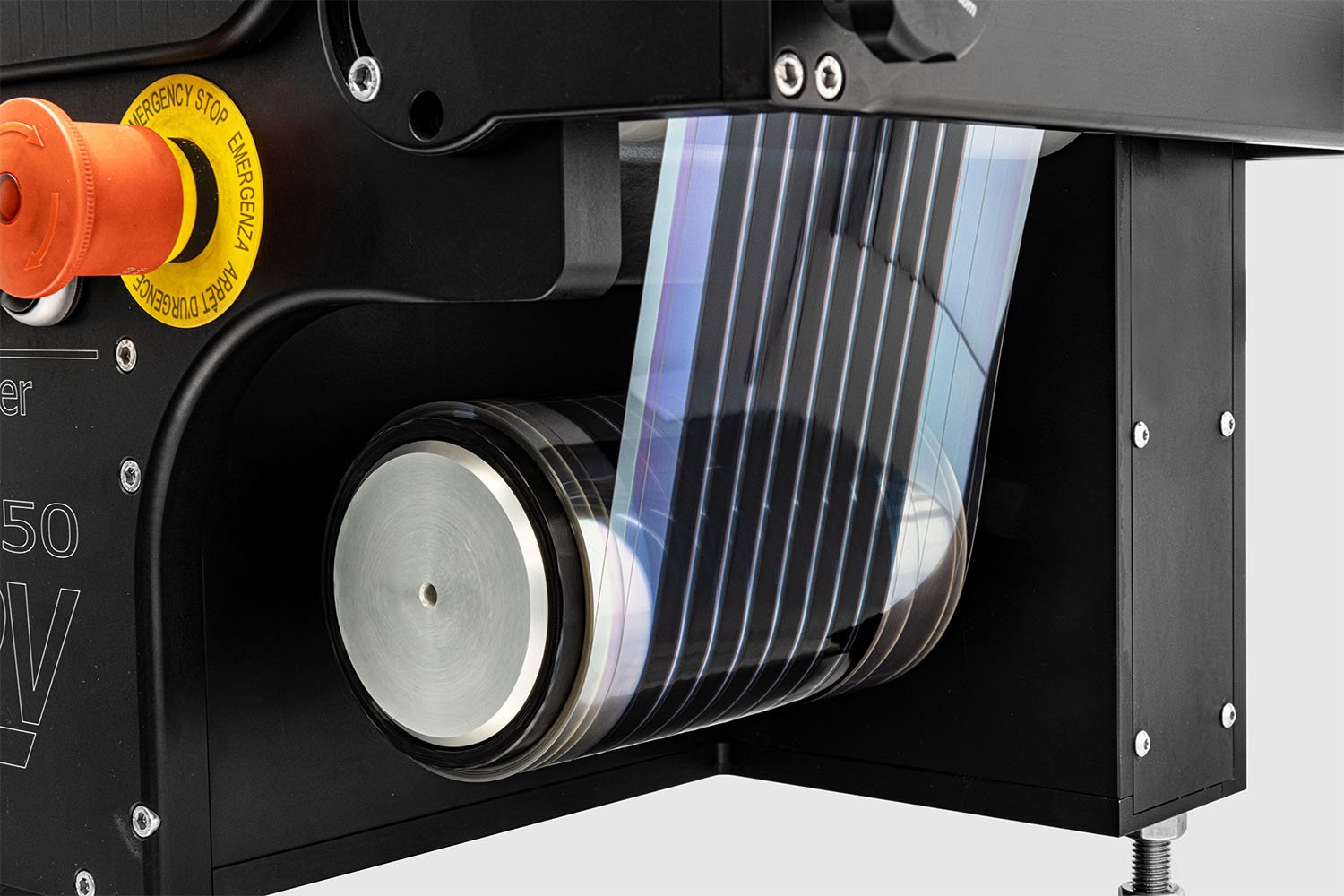

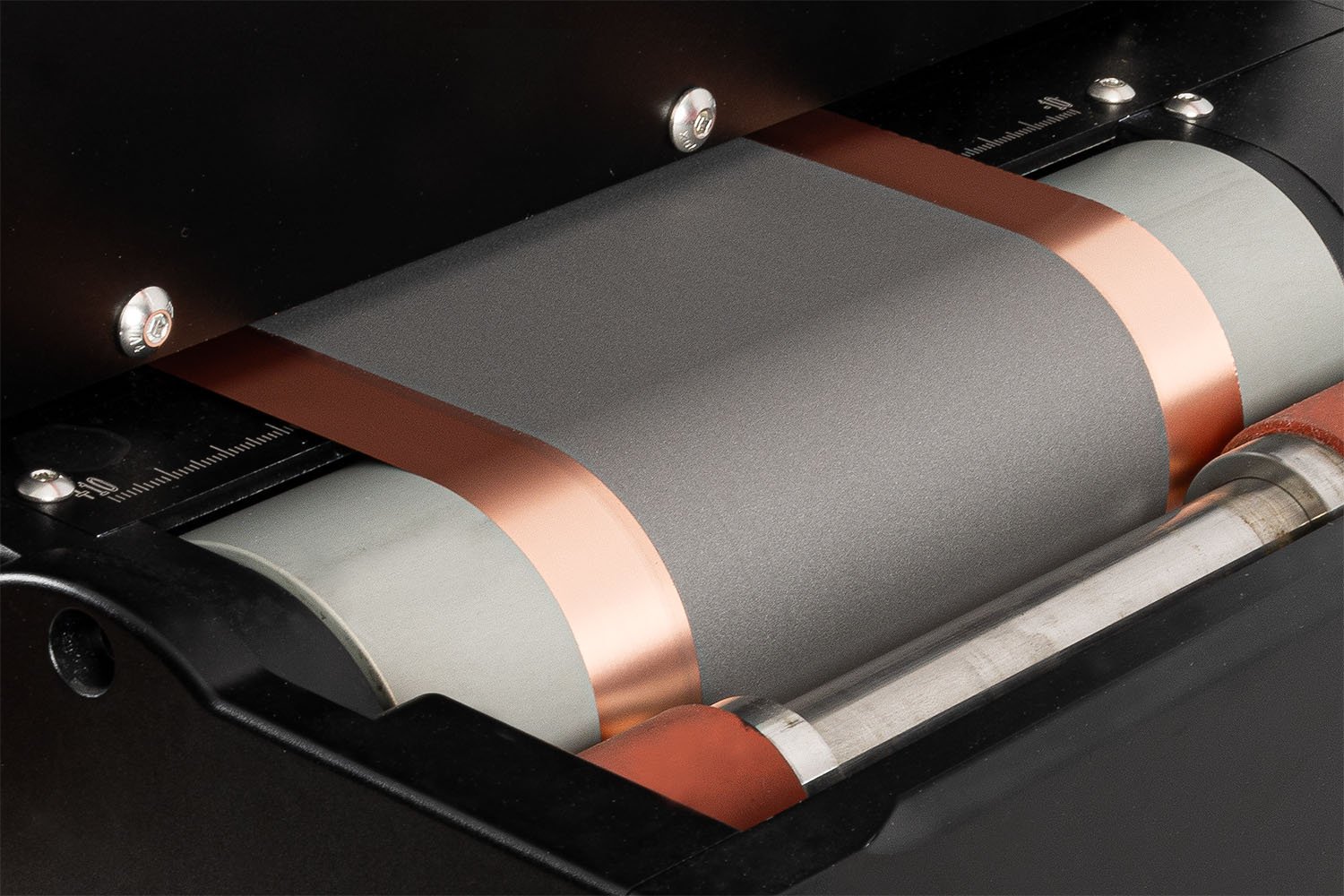

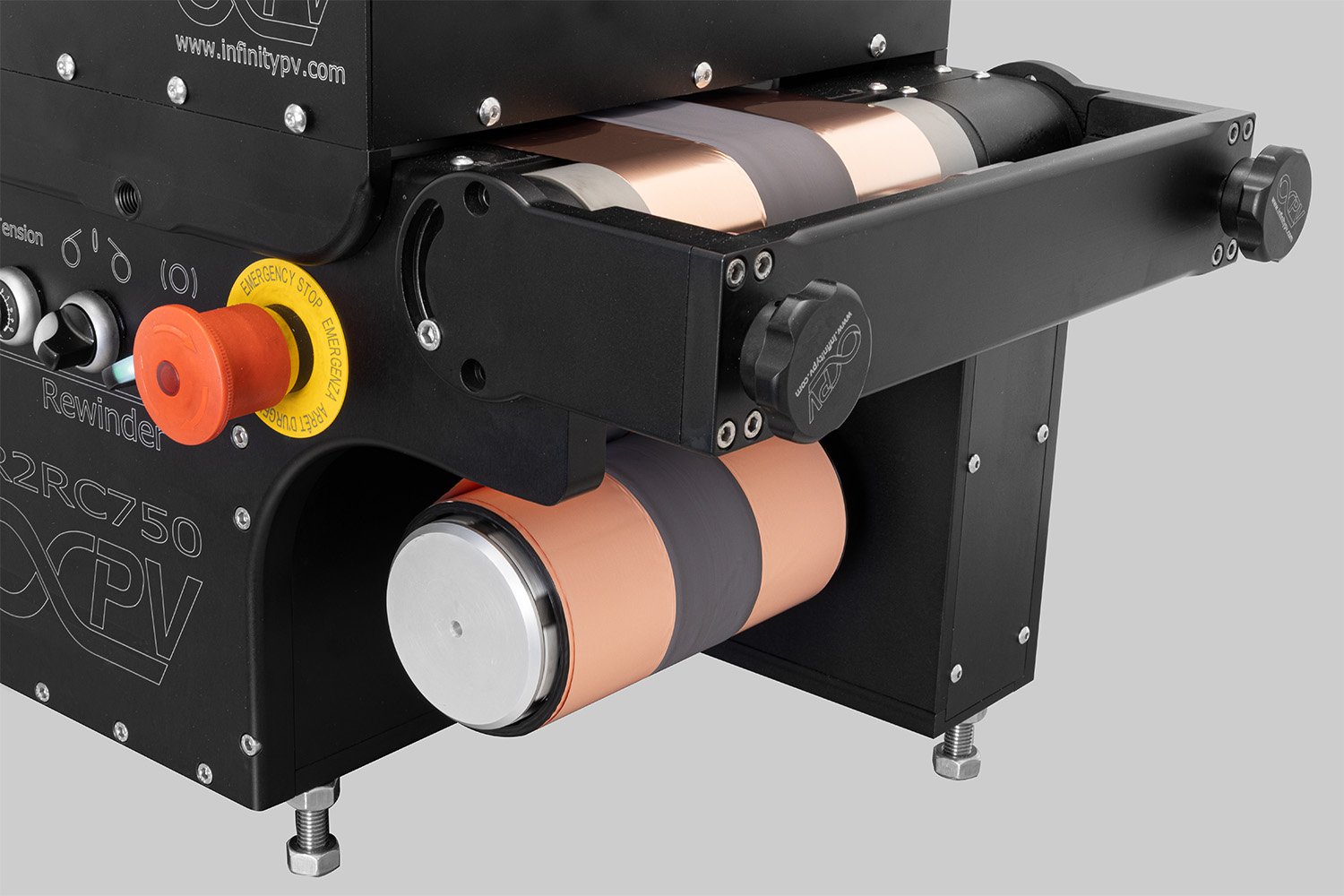

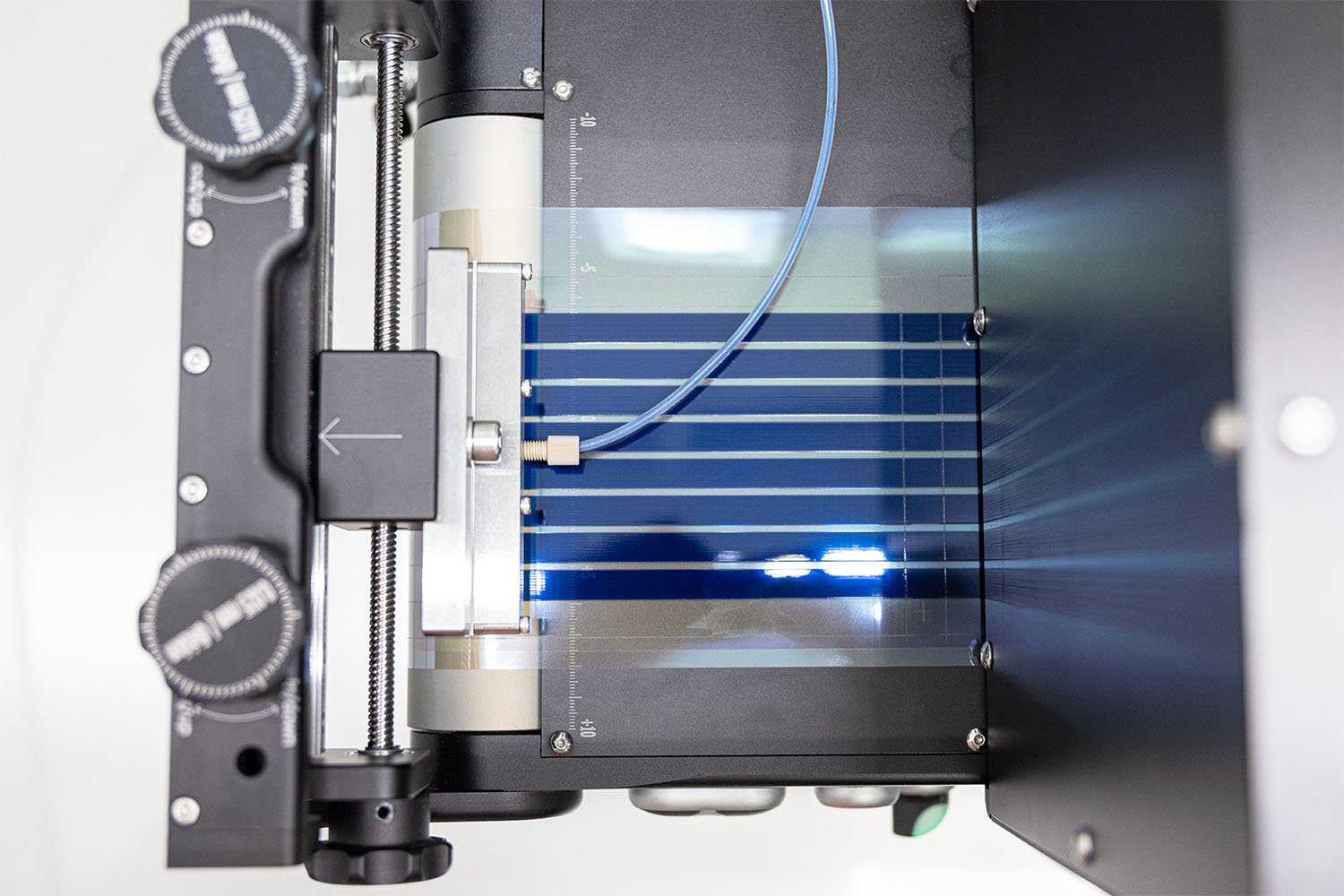

The Laboratory Roll-to-Roll Coater (LR2RC) revolutionizes the processing of thin functional films with its compact, high-precision design. Ideal for both lab research and small-scale pilot production, this versatile system efficiently processes hundreds of meters of foil. Its modular structure allows for extensive customization, including the choice of unit size and components like slot-die heads, slurry coaters, flexographic printers, syringe pumps, gear pumps, drying systems, and roll-to-roll laminators. Designed for seamless integration into existing lab setups, it bridges the gap between research and production, making it perfect for applications such as batteries, fuel cells, printed solar cells, and sensors. With user-friendly features and adherence to international safety standards, the Laboratory Roll-to-Roll Coater offers a reliable, scalable, and efficient solution for a wide range of industries. Ready to build your Own Laboratory Roll-to-Roll Coater? Start the customizer here.

Technical Specifications

Web Speed 0.05-2.8 m/min

Working Width Up 200 mm

Up to 2 Oven Systems Can Be Mounted

Touch Screen

Buttons for Unit Operation (Option for Full Software Control)

Simple Computer Logging (Options Available)

Web Tension Control

Advanced Unwinder/Rewinder Mode

Spindles - Automatic Compressed Air for 3-Inch Core

Rollers in Anodized Aluminum (Options Available)

Operates from a Single Phase (240VAC)

Dimensions (WxDxH): 75 cm x 35 cm x 30 | Weight: 40 kg

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous accessories available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Applications

Batteries

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Medical Devices (Biocompatible and Drug-eluting Layers)

Packaging Materials