Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

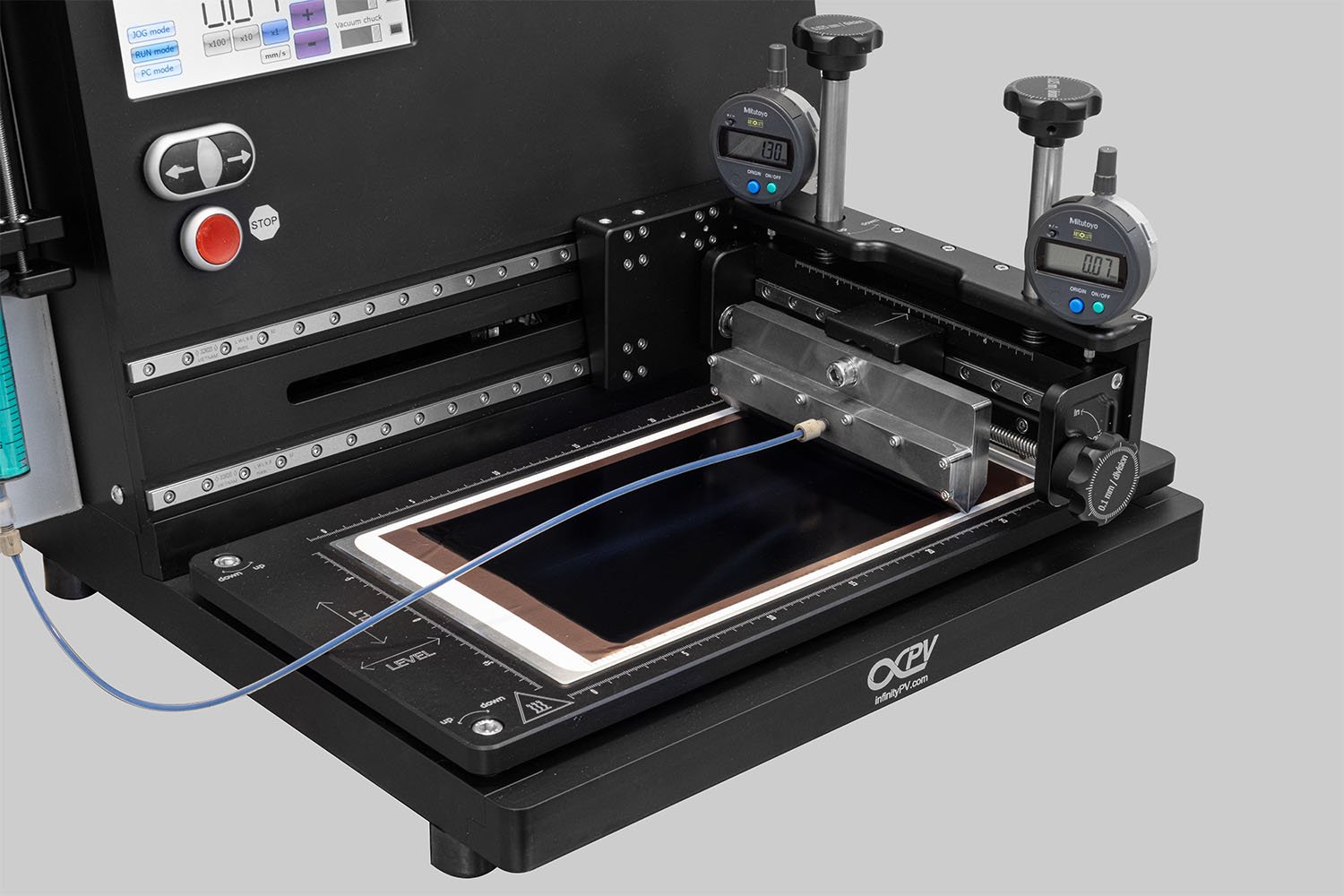

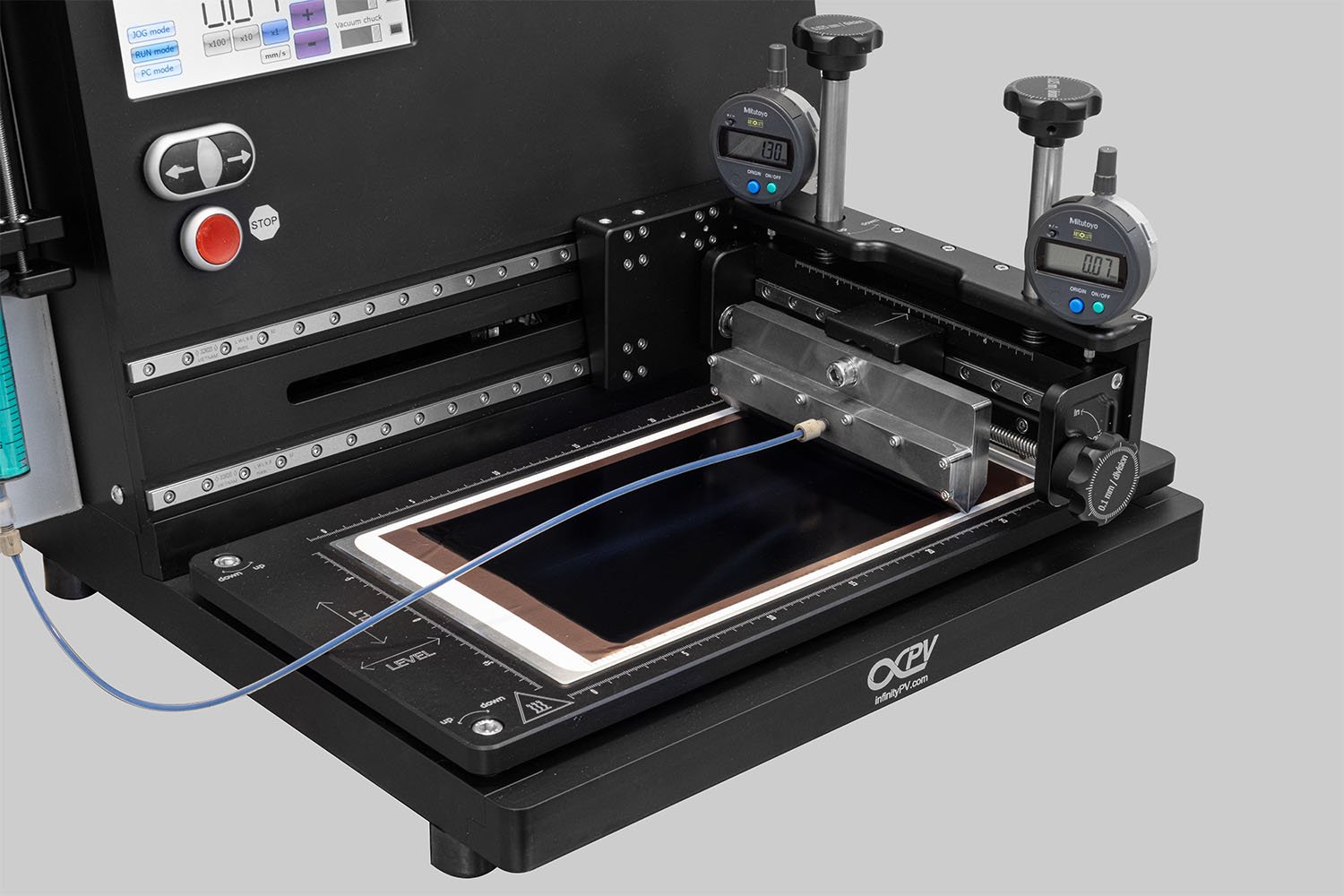

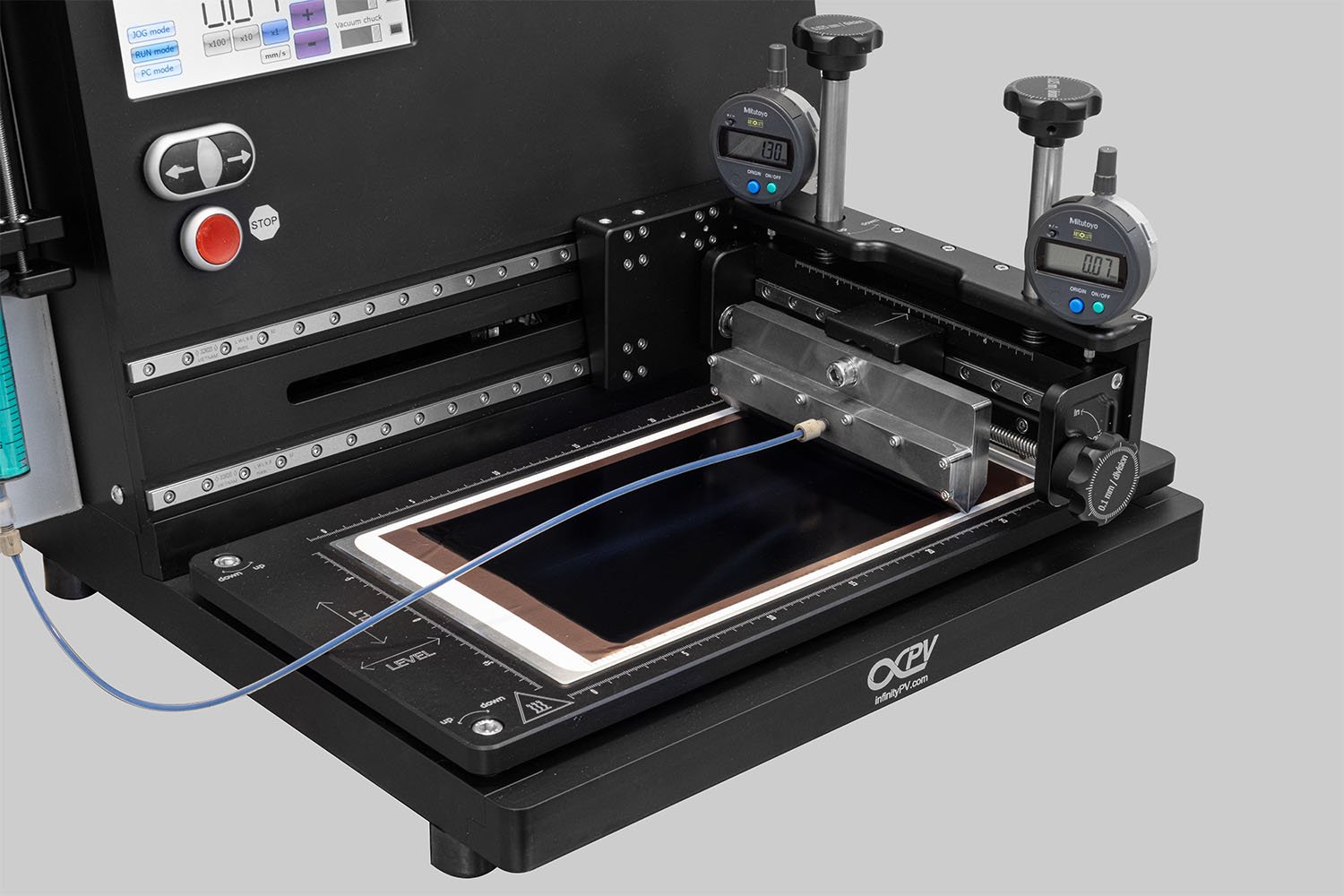

SDC Battery Coater Pro

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.

The Next Step in Scalable Battery Production

The SDC Battery Coater Pro, which is based on the Slot-die Coater platform, is an excellent choice for researchers focused on developing and optimizing battery electrode slurries at the laboratory scale. This slot-die coating technology offers precise control over the coating thickness, while the vacuum chuck ensures a smooth and even coating surface.

Key Features

Quick Set-Up and Easy Operation

Modular Design with interchangeable components

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Cantilever Structure for convenient substrate handling

Integrated Syringe Pump for precise ink delivery

Versatile Coating/Printing Options: Slot-Die Coating, Bar Coating, Knife Coating, Pen, and Flexo Printing

CE Certified - CSA/UL Compliant: Meets international safety standards

Technical Specifications

Operating Power: 110-240 VAC

Coating Speed: 1.2–33 mm/sec

Size: 340 x 420 x 400 mm (WxDxH)

Weight: 24 kg

Height Adjustment Resolution: 1 μm

Control Interface: Touchscreen and physical buttons for easy operation

What’s Included:

Slot-die Coater Pro: State-of-the-Art Slot-Die Coater for Advanced Thin-Film Applications

Advanced Mounting System: Advanced positioning of the slot-die heads

Heated Vacuum Chuck: Integrated heated vacuum chuck for workholding of thin foils and convenient drying of processed thin films

Jumbo Syringe Pump: For smooth ink delivery to the slot-die head

165 Stainless Slot-die head (150 mm working width): Ensures uniform and high-quality coating results

Fitting Kit (High viscosity)

Why Choose the SDC Battery Coater Pro?

The SDC Battery Coater Pro is ideal for research and development of battery electrode coatings due to its precise control over coating thickness and provision of a smooth coating surface. Designed for laboratory-scale applications, it offers flexibility for optimizing materials, which can later be scaled up for production.