The infinityPV Roll-to-Roll Academy aims to educate and engage people, enabling them to explore the potential of R2R applications in their respective field of technology, like next-gen batteries, fuel cell technologies, printed solar, and beyond.

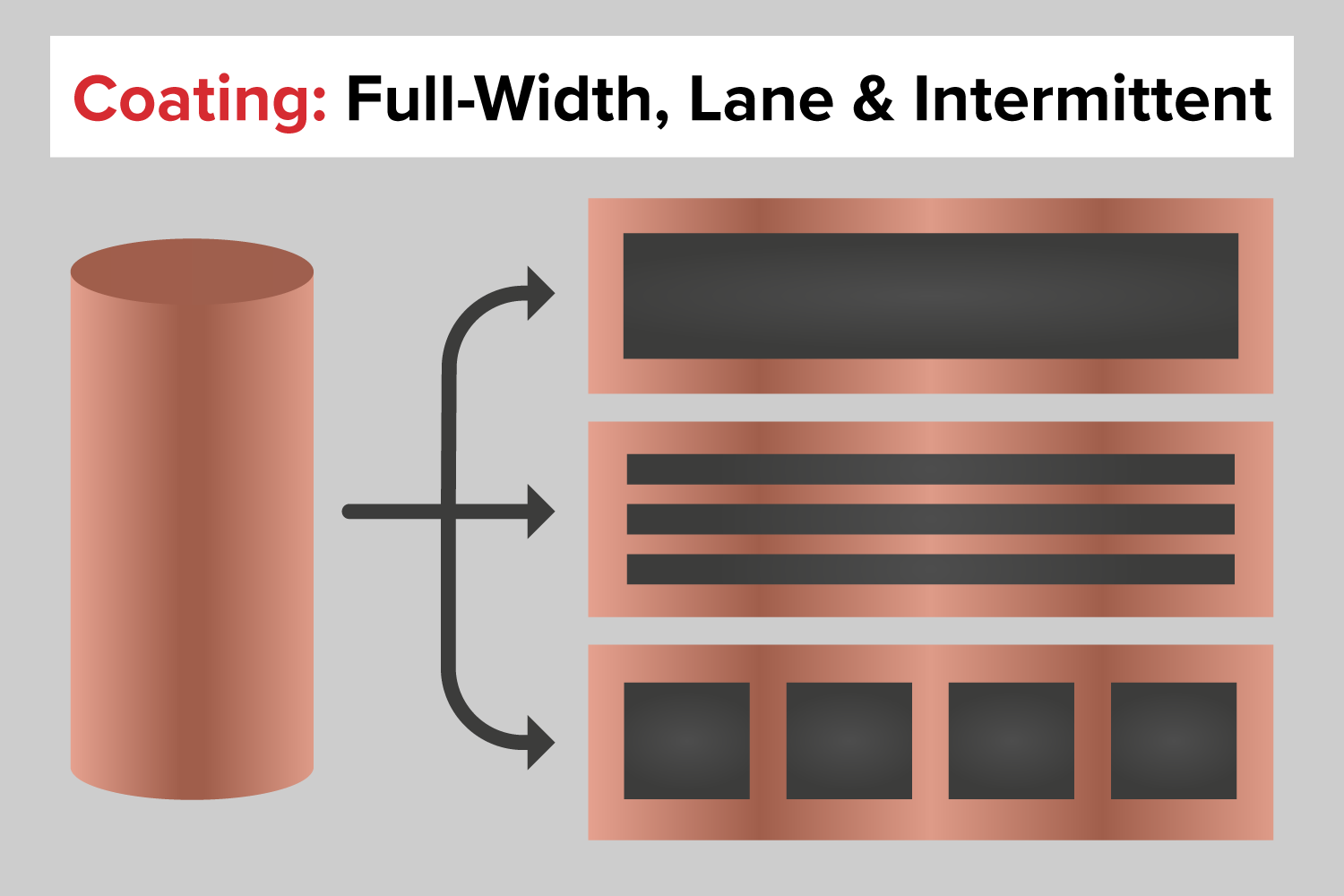

Roll-to-Roll Slot-Die Coating: Full-Width, Lane, and Intermittent Coating Techniques Explained

Explore full-width, lane, and intermittent slot-die coating methods, design challenges, and industrial applications.

Roll-to-Roll Coating vs. Sheet Coating: What’s the Best Method for Your Application?

Learn the key differences between roll-to-roll (R2R) and sheet coating techniques. Discover their advantages, challenges, and ideal applications to choose the right coating method for your lab or production needs.

What is a Roll-to-Roll Coater? A Guide to Continuous Thin-Film Coating and Processing

Discover how roll-to-roll coaters enable continuous thin-film deposition on flexible substrates. Learn about slot-die coating, scalability, and lab-to-production transition with expert tips from infinityPV.

What is Corona and Plasma Surface Treatment?

Surface treatment technologies like plasma and corona are crucial for enhancing the adhesion of inks, coatings, and adhesives, particularly when working with non-porous materials like plastics and polymers.

Roll-to-Roll Manufacturing of Batteries: A Revolution in Energy Storage

As the demand for renewable energy solutions and portable electronic devices grows, the need for efficient and scalable battery manufacturing processes has never been more critical.

What is Roll-to-Roll Processing?

Roll-to-roll (R2R) processing is a manufacturing technique used primarily for producing flexible materials and components, such as plastic films, paper, or metal foils, coatings, and electronic components, by processing them in a continuous roll format.

Build Your Own R2R Lab Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.