What is Corona and Plasma Surface Treatment?

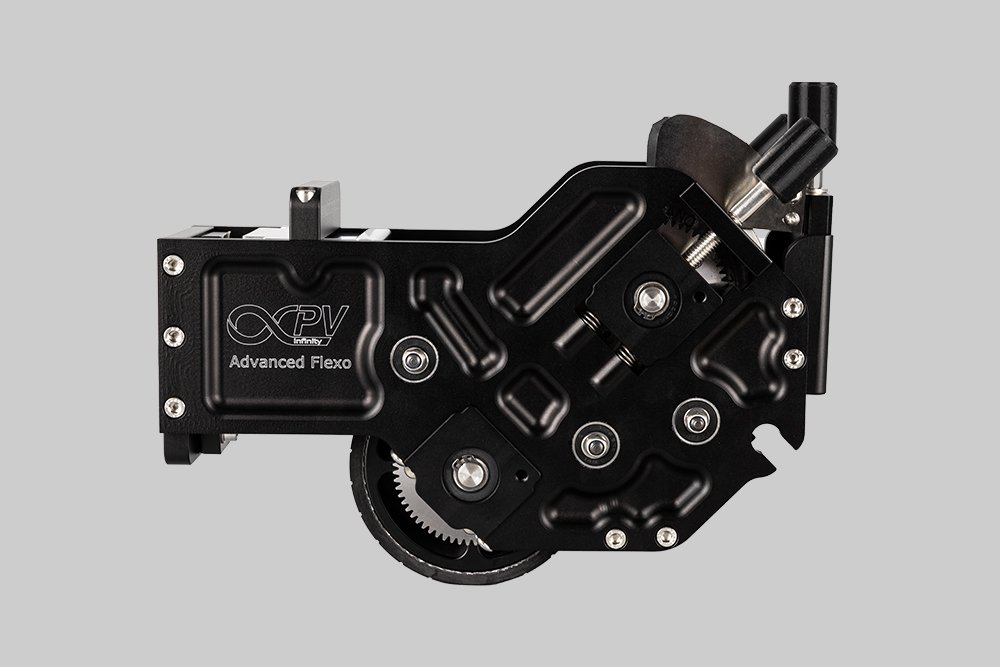

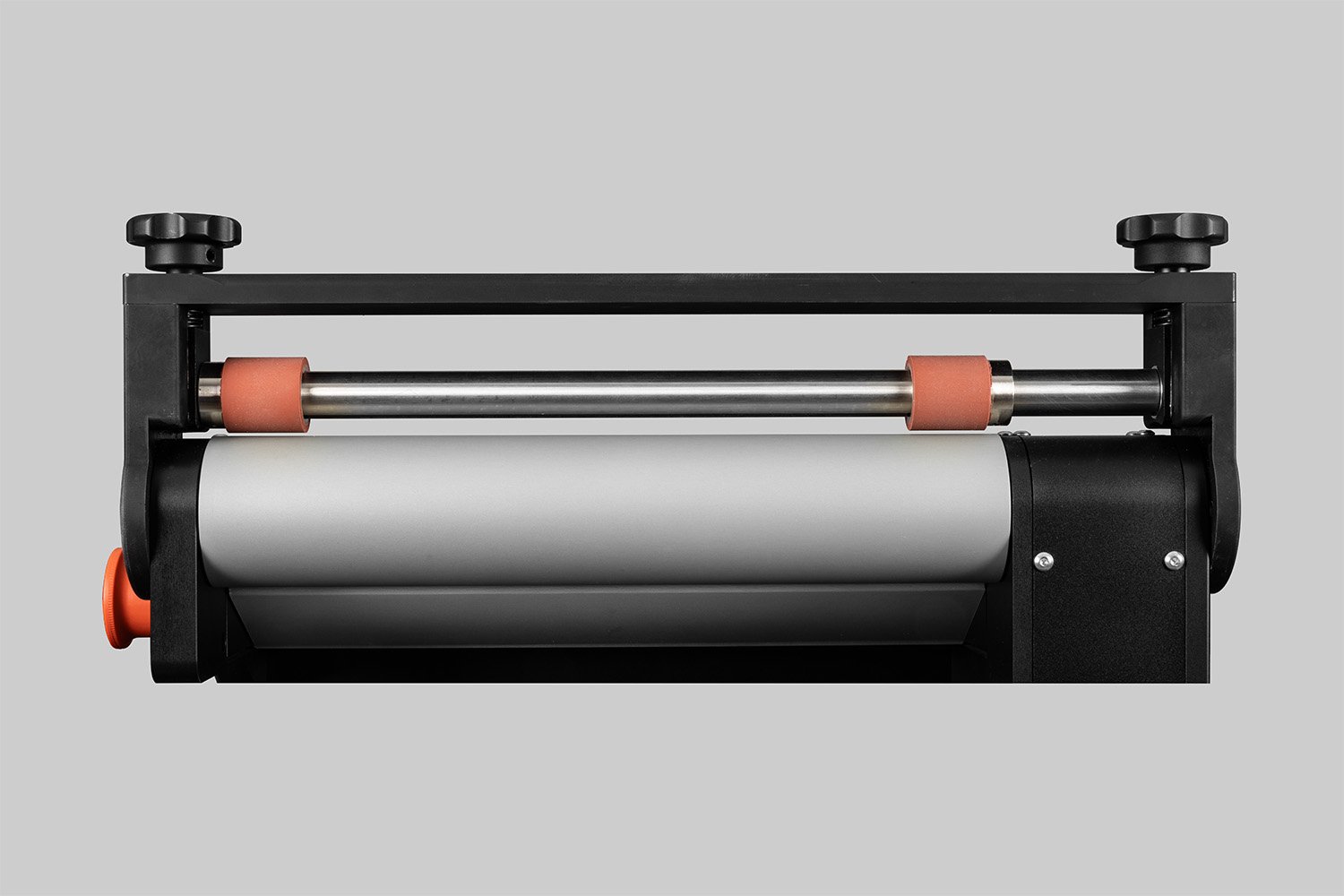

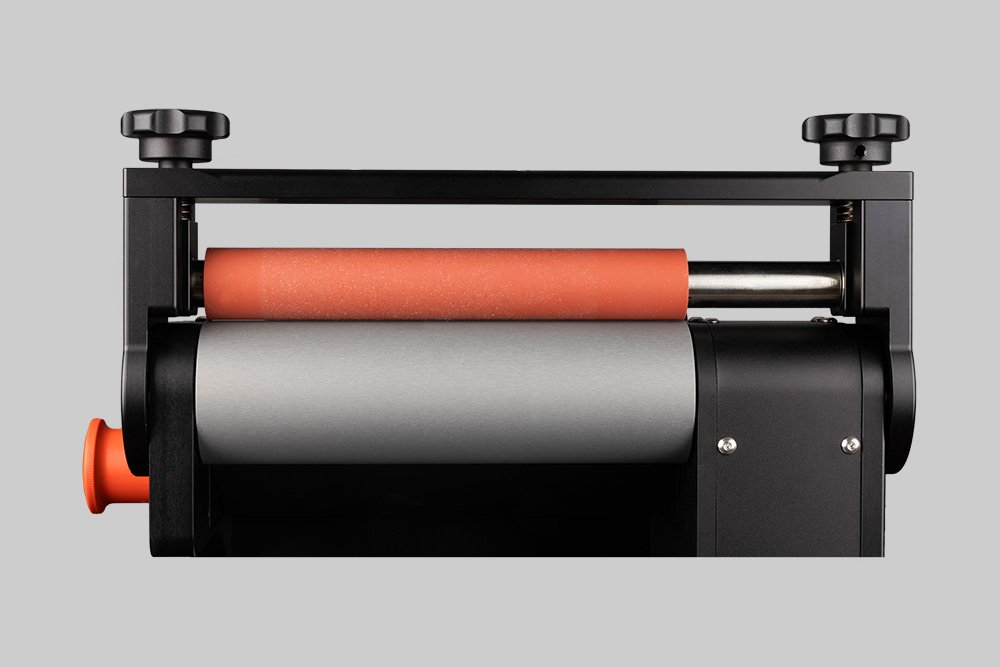

Corona treatment of plastic foil for roll-to-roll processing using a corona surface treater.

Understanding Plasma and Corona Surface Treatment for Enhanced Adhesion

Surface treatment technologies like plasma and corona are crucial for enhancing the adhesion of inks, coatings, and adhesives, particularly when working with non-porous materials like plastics and polymers. These techniques modify surface energy, making typically hydrophobic surfaces more hydrophilic, which results in better wettability and bonding. This article explores the fundamentals of plasma and corona surface treatments, explains how they combat dewetting, and highlights their advantages in industrial applications.

What is the advantage of Corona surface treatment?

Dewetting and Wetting Explained

Dewetting is a common challenge in many industrial applications, particularly in coating or printing processes. The phenomenon occurs when a liquid, such as ink or adhesive, does not spread evenly across a surface. Instead, it forms droplets or beads—similar to how oil behaves when added to water. This happens due to a mismatch in surface energy: hydrophobic surfaces (low surface energy) repel hydrophilic liquids (high surface energy), causing poor wetting.

In practical terms, this can be problematic. For instance, when an ink or coating is applied to a plastic film, if the surface energy is too low, the liquid will bead up rather than spread, leading to poor coverage and weak adhesion. To address this, surface treatments like corona and plasma are used to increase the surface energy, improving wettability and ensuring that liquids spread uniformly.

Wetting: Good adhesion occurs when a liquid spreads on the surface, indicating compatibility between liquid and surface energy.

Dewetting: Results from surface energy mismatch, where the liquid beads up and fails to spread uniformly.

Web Surface Treatment: Raising Surface Energy for Better Adhesion

Both plasma and corona treatments work by raising the surface energy of materials to promote better wetting and adhesion. These techniques are especially useful for polymers, foils, and other flexible substrates that typically have low surface energy. The goal is to modify the surface at a molecular level to make it more hydrophilic, thus improving its interaction with liquids like inks, coatings, or adhesives.

What is corona treatment?

Corona Surface Treatment: What It Is and How It Works

Corona surface treatment is a critical process in industrial applications for enhancing the adhesion properties of materials, particularly non-porous substrates like plastics and films. This technology increases surface energy, making materials more receptive to inks, coatings, and adhesives—essential for industries such as printing, packaging, and labeling.

How Does Corona Surface Treatment Work?

A typical corona treatment setup consists of a high-voltage power supply and electrodes, often attached to a metal roller. When high voltage is applied, the air surrounding the electrodes becomes ionized, creating a “corona discharge.” This discharge releases reactive ions and radicals, which interact with the material’s surface, breaking chemical bonds and introducing new functional groups like hydroxyl or carbonyl groups. These functional groups increase the surface energy, improving adhesion. However, the effectiveness of corona treatment diminishes over time. The surface treatment may degrade due to contamination or physical wear, so it’s often necessary to use the treated material relatively soon after the process to ensure maximum adhesion.

Applications of Corona Surface Treatment

Flexible Packaging: Enhances ink adhesion on plastic films.

Printed Electronics: Improves surface properties for conductive inks.

Laminating and Bonding: Ensures strong adhesive bonds between materials.

Benefits of Corona Surface Treatment

Enhanced Adhesion: Improves bonding of inks and coatings, ensuring better product quality.

Cost-Effective: More economical than chemical primers or plasma treatments.

Speed and Efficiency: Integrates seamlessly into high-speed production lines.

Eco-Friendly: Reduces reliance on harmful chemicals by using electrical energy.

What is plasma treatment?

Plasma Surface Treatment: A Versatile Solution for Advanced Applications

Plasma surface treatment is a cutting-edge technique utilized in industrial applications to enhance the surface properties of materials, improving their adhesion, wettability, and cleanliness. This method is particularly effective for treating non-porous substrates, including plastics, metals, and glass, making it indispensable in sectors such as packaging, electronics, and automotive.

Compared to corona treatment, plasma surface treatment offers a more advanced and versatile approach. While corona treatment operates effectively at atmospheric pressure, plasma treatment can be conducted in low-pressure or vacuum environments. This capability allows for greater precision in controlling the surface modification process, resulting in superior performance and improved material compatibility.

How Does Plasma Surface Treatment Work?

In plasma treatment, a gas (such as argon, oxygen, or nitrogen) is ionized by applying a high voltage, resulting in a plasma state—a mixture of ions, electrons, and neutral particles. When a substrate is exposed to this plasma, reactive species interact with its surface, breaking chemical bonds and introducing new polar groups. Plasma treatment also serves a dual purpose by simultaneously cleaning the surface, removing contaminants such as dust, oils, and residues that could otherwise hinder adhesion. This dual-function capability—cleaning and modifying—makes plasma treatment especially valuable in high-performance industries, including aerospace, medical technology, and electronics, where even microscopic impurities can interfere with bonding.

Generation of Plasma: A gas (such as argon, oxygen, or nitrogen) is ionized in a vacuum or low-pressure chamber, creating a plasma state—a mixture of ions, electrons, and neutral particles.

Surface Interaction: The reactive species generated in the plasma interact with the material’s surface, removing contaminants and modifying the chemical structure. This can introduce polar functional groups, such as hydroxyl or carbonyl groups.

Increased Surface Energy: The addition of polar groups increases the surface energy of the material, enhancing its ability to bond with inks, adhesives, and coatings.

Benefits of Plasma Surface Treatment

Improved Adhesion: Significantly enhances the bonding properties of inks and coatings, ensuring better quality and durability.

Effective Cleaning: Removes contaminants like oils, dust, and residues, leading to cleaner surfaces before further processing.

Versatility: Suitable for a wide range of materials, including plastics, metals, and ceramics.

Environmentally Friendly: Reduces the need for harsh chemicals, making it a safer option for surface modification.

Applications of Plasma Surface Treatment

Flexible Packaging: Enhances the adhesion of inks and coatings on packaging materials.

Printed Electronics: Improves the surface characteristics for better performance of conductive inks.

Automotive and Aerospace: Ensures strong bonding for components and coatings in high-performance applications.

By combining a roll-to-roll slot-die coater with a corona surface treater, you ensure enhanced adhesion, improved film uniformity, and increased coating efficiency on flexible substrates.

Comparing Corona and Plasma Surface Treatment

While both corona and plasma surface treatments aim to improve surface energy and adhesion, they differ in several key ways. Corona treatment is typically a more cost-effective solution for large-scale applications, such as printing on plastic films, and operates at atmospheric pressure. Plasma treatment, on the other hand, offers more precision and versatility, especially in sensitive applications where cleanliness and molecular-level modification are critical.

| Corona Treatment | Plasma Treatment |

|---|---|

| Works at atmospheric pressure | Can operate in vacuum or low-pressure environments |

| Lower cost and simpler setup | More expensive but offers greater precision |

| Commonly used in packaging and printing | Ideal for high-tech applications like aerospace and medical devices |

| Surface treatment may degrade quickly | Long-lasting effects, especially in vacuum applications |

Why Surface Treatment is Essential for Adhesion

Surface treatment technologies are essential in industrial processes that require optimal adhesion of coatings, inks, and adhesives. Without proper surface modification, dewetting can occur, leading to poor adhesion, reduced product quality, and increased waste. Both corona and plasma surface treatments offer reliable solutions for enhancing surface energy and improving the wettability of materials. Corona treatment is ideal for cost-effective, large-scale applications, whereas plasma treatment is better suited for high-precision, advanced applications where both cleanliness and molecular modification are crucial.

Slot-die coating is an efficient method for applying uniform thin films onto substrates, ideal for applications like electronics and flexible packaging. Learn more about slot-die coating here.

How Surface Treatment Enhances Slot-Die Coating

Incorporating plasma surface treatment into the roll-to-roll manufacturing process significantly elevates the quality of slot-die coatings, leading to improved product performance, efficiency, and cost-effectiveness. By optimizing the surface properties of substrates, manufacturers can achieve superior wettability and adhesion, resulting in more uniform and durable coatings. As the demand for high-performance films and coatings continues to grow, the integration of innovative surface treatment technologies, such as plasma treatment, will play an increasingly crucial role in advancing manufacturing processes.

Enhanced Wettability: One of the primary challenges in slot-die coating is ensuring that the coating fluid spreads evenly across the substrate. Plasma treatment markedly increases the surface energy of treated materials, improving wettability. This enhancement allows the coating fluid to spread uniformly, minimizing defects like streaks, skips, or puddles, and ultimately yielding a smoother finished film.

Improved Adhesion: The introduction of polar functional groups on the surface through plasma treatment promotes stronger chemical and physical bonding between the substrate and the coating material. This increased adhesion is especially vital in applications such as electronics and packaging, where delamination can undermine functionality. By ensuring a robust bond, manufacturers can significantly enhance the durability and longevity of coated products.

Reduction of Coating Weight: The superior wettability and adhesion achieved through plasma treatment enable the application of thinner coating layers without compromising quality. This reduction in coating weight leads to material savings and improved manufacturing efficiency, making processes more sustainable and cost-effective.

Uniform Coating Thickness: Achieving a consistent film thickness is essential for performance consistency in slot-die coating. Plasma treatment aids in regulating the flow and distribution of the coating material, facilitating the creation of a uniform film even at high production speeds. Enhanced control over the coating process translates to better optical and mechanical properties in the final product.

Compatibility with Various Substrates: Plasma treatment can be tailored to meet the specific needs of a wide range of substrates, including plastics, metals, and glass. This versatility enables manufacturers to apply slot-die coating across various applications, addressing unique requirements related to surface properties and functionality.

Conclusion: Choosing the Right Surface Treatment for Your Application

In summary, both plasma and corona surface treatments are essential techniques for enhancing material adhesion by increasing surface energy. While corona treatment is particularly well-suited for high-speed, large-scale processes like printing and labeling, plasma treatment provides superior precision and versatility, making it ideal for advanced applications in electronics, medical technology, and aerospace.

Understanding the distinctions between these two methods is crucial for selecting the right surface treatment for your specific needs. For instance, if your application involves slot-die coating, the choice between cost-effective corona treatment and the precision offered by plasma treatment can significantly impact the quality and performance of the final product. Both methods play a pivotal role in optimizing adhesion and ensuring uniform coatings, ultimately leading to enhanced product durability and functionality. By leveraging the appropriate surface modification technology, manufacturers can meet the growing demands for high-performance materials across various industries.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.